DC Planetary Gear Motor Manufacturer

We design high-precision DC motors with planetary gearboxes using MIM technology, offering compact, durable, high-torque solutions for robotics, automotive, and smart devices.

We offer flexible customization to meet specific voltage, torque, and dimensional requirements, delivering reliable and efficient motion control tailored to your needs.

- Diameter: 6mm,24mm,28mm,32mm,38mm, 42mm

- Material: Metal,plastic

- Speed: 5 RPM - 100000 RPM

- Torque: 1.0 mNm-200000mNm.

Home / DC Planetary Gear Motor

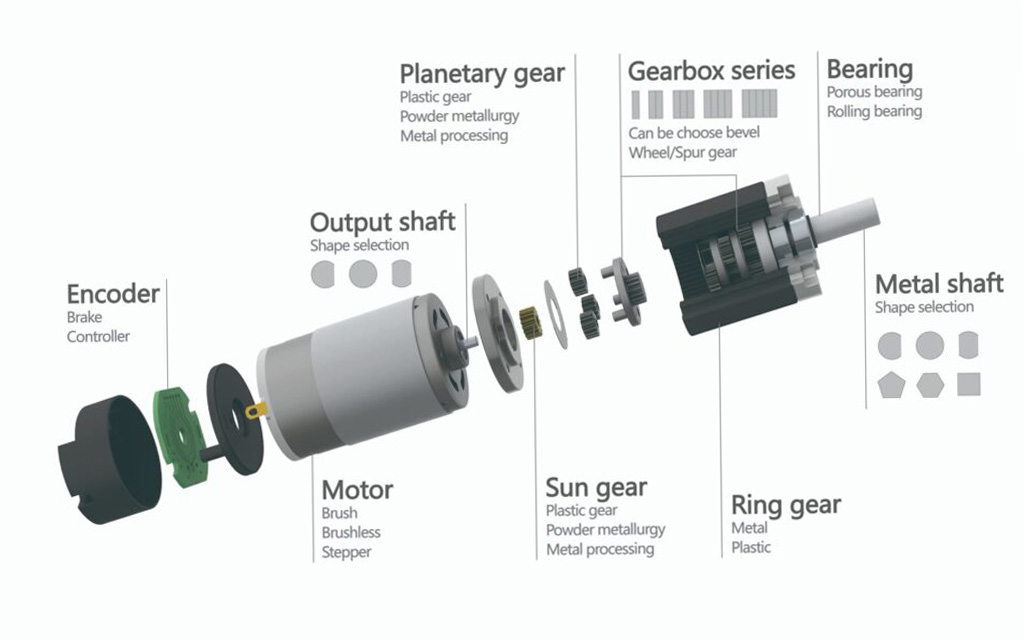

Structure

The structure of planetary gearbox with motor generally follows a specific arrangement to achieve its functionality

Motor

- Core component that provides the rotational power.

- brushless motor or brushed motor.

Sun Gear

- Center of gearbox, driven by input shaft.

- Transfers motion to the planet gears.

Planet Gears

- Planet gears meshing with sun and ring.

- Carrier-mounted ensures even load distribution & high torque.

Planet Carrier

- Secures planet gears, enabling free rotation.

- Transfers combined torque to output shaft.

Ring Gear

- Large gear encircles and engages planet gears.

- Fixed or rotating, adjusts gear ratio.

Output Shaft

- Connected to the planet carrier.

- Delivers the output power to the driven equipment.

By Commutation Type

We can custom and manufacture brushed and BLDC planetary gear motors for you, making your project more cost-effective.

Brushless

- BLDC planetary gear motor features electronic commutation with magnets, eliminating brushes for reduced wear.

- With a diameter of 20mm-28mm, it operates at a rated speed of 5rpm-2000rpm and delivers torque between 500mNm and 4000mNm.

- It offers longer lifespan, low maintenance, and enhanced speed and torque control.

Brushed

- Brushed planetary gear motor features mechanical commutation with brushes that wear out over time.

- It has a diameter range of 6mm to 42mm, a rated speed of 4rpm to 12,000rpm, and torque between 1mNm and 160,000mNm.

- It provides simpler control but has a shorter lifespan, needing regular brush replacement.

From 0 to N - Full Motor Solutions

By Number of Stages

Our DC planetary gear motors offer single, two, or multi-stage options for tailored efficiency, torque, and reduction ratio performance across applications.

Single-stage Planetary Gear Motor

- One set of planetary gears.

- Higher efficiency, lower reduction ratio (3:1 to 10:1).

- Efficiency above 95%.

- Suitable for low-to-medium torque needs, such as electric tools, actuators, or compact robotics.

Two-stage Planetary Gear Motor

- Two gear sets in sequence.

- Moderate torque and medium reduction ratios (10:1 to 100:1).

- Efficiency is 90% to 94%.

- Used in moderate-load applications like conveyors, medical equipment, and precision drives.

Multi-stage Planetary Gear Motor

- Three or more stages.

- High torque and large reduction ratios (over 1000:1).

- Efficiency is 80% to 90%.

- Best for high-torque, low-speed tasks such as industrial automation, robotics arms, and packaging machines.

By Material

We use MIM technology to customize the material of the planetary gearbox,including plastic and metal.

Plastic

- Plastic planetary gear motors consist of plastic planetary gears and a motor.

- They are affordable, customizable in shape and size for specific designs.

- Suitable for lighter loads, operate quietly, ideal for specific applications.

Metal

- Metal planetary gear motors consist of steel,brass or aluminum planetary gears & a motor.

- Higher durability and wear resistance, suitable for heavy-duty applications.

- Better heat dissipation and resistance, ideal for high-temperature environments.

Featured products

TR039-P01 Brushed Planetary Gear Motor

- Rated voltage:DC12V

- No-load speed:255±25.5RPM

- Locked-rotor current: 3.78N.m~4.62N.m

TR067-P01 Brushed Planetary Gear Motor

- Rated voltage: DC18V

- No-load speed: ≤0.75A

- No-load speed:460±10%RPM

TR075-P07 Brushless Planetary Gear Motor

- Rated voltage: DC12V

- Rated speed:40±15%RPM

- Rated moment:1.176N.m

TR075-P08 Brushless Planetary Gear Motor

- Rated voltage: DC12V

- Rated speed:21.6±15%RPM

- Rated moment:1.8N.m

Customer Case

Planetary Gear Motor for Vacuum Cleaner Brush

A home appliance company approached us seeking a cost-effective motor solution for their vacuum cleaner’s roller brush.

Understanding that the roller brush typically has a limited service life—often under 200 hours—we developed a 12V brushed DC motor with a 30:1 planetary gearbox, delivering 0.8 Nm torque. By selecting a brushed motor instead of a brushless alternative, we helped reduce the customer’s cost by approximately 40%, making it more suitable for disposable or replaceable components in household vacuum systems.

This solution successfully balanced performance with cost-efficiency, aligning perfectly with the client’s product life cycle strategy.

Applications

Robotics

- Robotic Arms: Guarantees accurate control and mobility for jobs involving welding, painting.

- Automated Systems: Enables accurate navigation and operation in mobile robots and AGVs.

Automotive

- Electric Power Steering (EPS): Provides variable steering assistance for enhanced comfort and control.

- Window& Seat: Ensure smooth, reliable operation and precise adjustment for comfort and safety.

Industrial Machinery

- Conveyor Systems: Enables efficient, controlled goods movement in manufacturing lines.

- Packaging Machines: Ensures precise control, high torque for packaging operations.

Medical Devices

- Surgical Robots: Provides precise control and movement for minimally invasive surgeries.

- Diagnostic Equipment: Enables precise positioning in MRI and CT scanners.

Aerospace

- Actuators: Adjusts control surfaces in flight systems like ailerons and elevators.

- Landing Gear Systems: Ensures reliable control of landing gear retraction and extension operations.

Renewable Energy

- Wind Turbines: Provides efficient and reliable torque transfer for the rotation of turbine blades.

- Solar Tracking Systems: Maximizes sunlight exposure by accurately positioning solar panels.

FAQ

What distinguishes a planetary gear motor from a conventional gear motor?

The primary difference is in the gear arrangement and efficiency. Planetary gear motors offer higher torque, compact size, and better load distribution compared to regular gear motors.

How do you select the right planetary gear motor for your application?

Selection involves considering factors such as required torque, speed, size constraints, efficiency, and the specific application's load conditions and duty cycle.

Can hydraulic motors with planetary gearboxes be customized?

Yes, customization options are available to meet specific application requirements, including custom gear ratios, materials, mounting configurations, and hydraulic motor specifications.

What materials are used in the construction of stepper motors with planetary gearboxes?

Materials commonly used include high-strength steel for gears and shafts, aluminum or steel for the motor housing, and durable seals and bearings to ensure long-lasting performance.