Brushless DC (BLDC) motors are highly valued for their dependability, efficiency, and longevity in a variety of applications, from home appliances and industrial machinery to electric cars and drones. Despite their robust design, BLDC motors are not immune to failure. Understanding the most common failure modes, their causes, and preventive measures is essential for ensuring their longevity and consistent performance.

How BLDC Motors Work

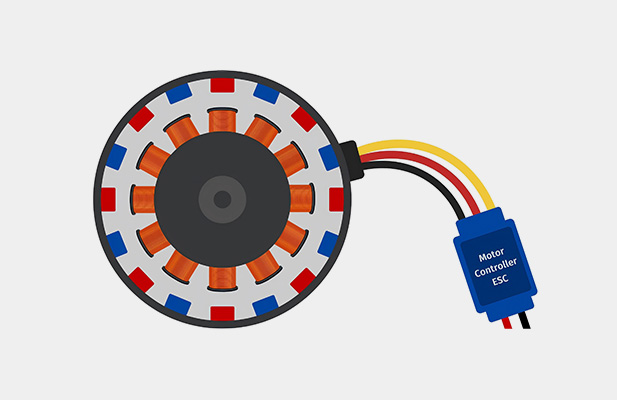

To understand potential failures, it’s helpful to first review how a BLDC motor operates. Unlike brushed motors, BLDC motors rely on electronic commutation, where the switching of current is controlled by an electronic speed controller (ESC) rather than physical brushes. The motor’s primary components are as follows:

- Stator: The motor’s stationary winding-containing component.

- Rotor: The rotating part with permanent magnets.

- Hall Sensors: Detect rotor position for precise commutation (in sensored motors).

- ESC: Controls current flow, timing, and speed.

While the absence of brushes reduces wear and tear, failures can still occur in other components or due to operational stresses.

The Most Typical Reasons for BLDC Motor Failures

The most prevalent failure in BLDC motors can generally be traced to overheating, which often leads to damage to the windings or magnets. However, there are several other significant failure modes, including electrical, mechanical, and operational issues.

Overheating

Overheating is the leading cause of failure in BLDC motors. Excessive heat can degrade insulation in the stator windings, demagnetize the rotor magnets, or cause permanent damage to electronic components.

Causes of Overheating:

- Overloading: Excessive heat is produced when the motor is operated above its rated capability.

- Poor Ventilation: Inadequate airflow or cooling mechanisms result in heat buildup.

- Inefficient Heat Dissipation: Lack of thermal management can cause heat to accumulate in the motor.

Effects:

- Burnt Windings: Overheated windings can lose their insulation, leading to short circuits.

- Demagnetization of Magnets: Permanent magnets lose their magnetic properties at high temperatures, reducing motor performance.

Prevention:

- Match the motor to the application load.

- Use proper heat sinks, fans, or liquid cooling systems.

- Monitor operating temperatures with thermal sensors.

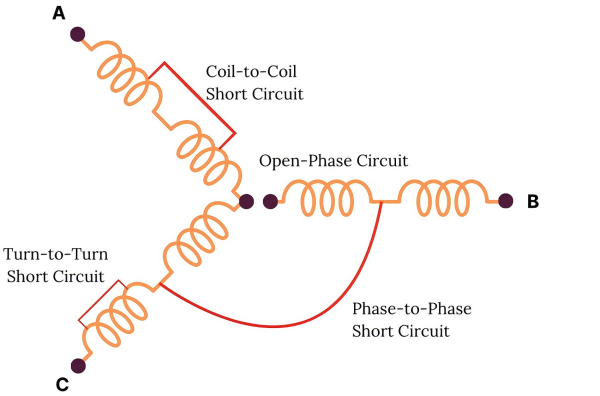

Insulation Failure

To stop electrical short circuits, insulating material is applied to the stator windings. Over time, this insulation can degrade due to thermal, mechanical, or electrical stresses.

Causes:

- Thermal Stress: Constant overheating weakens insulation.

- Mechanical Damage: Vibration or improper handling can compromise insulation.

- Voltage Surges: High voltage spikes from the ESC can puncture insulation.

Effects:

- Short Circuits: Leads to winding failures and motor damage.

- Reduced Efficiency: Causes uneven current distribution and higher power loss.

Prevention:

- Use high-quality motors with durable insulation materials.

- Install voltage regulators to prevent spikes.

- Minimize vibrations with secure mounting and balancing.

Bearing Failure

Bearings facilitate smooth rotation of the rotor. Bearing failure brought on by wear and tear over time can affect motor performance and produce noise during operation.

Causes:

- Excessive Load: High radial or axial loads can strain bearings.

- Lack of Lubrication: Dry or contaminated bearings increase friction.

- Environmental Factors: Dust, moisture, and contaminants can corrode or damage bearings.

Effects:

- Increased Friction: Leads to higher energy consumption and heat.

- Rotor Imbalance: Causes vibrations and noise, potentially damaging other components.

- Motor Seizure: In severe cases, the motor may stop functioning entirely.

Prevention:

- Use motors with high-quality sealed bearings.

- Conduct regular maintenance and lubrication.

- Operate the motor within its specified load limits.

Demagnetization of Rotor Magnets

Permanent magnets on the rotor are essential for producing the electromagnetic field needed for motor functioning. Demagnetization can drastically reduce motor efficiency and torque output.

Causes:

- Overheating: Excessive temperatures weaken the magnetic properties.

- High Current: Prolonged overcurrent conditions can damage magnets.

- Mechanical Impact: Physical shocks can dislodge or weaken magnets.

Effects:

- Reduced Torque: The motor’s torque-generating capacity decreases with decreasing magnetic strength.

- Operational Instability: Causes uneven performance and potential failure.

Prevention:

- Avoid overheating through proper cooling mechanisms.

- Use overcurrent protection circuits in the ESC.

- Handle the motor carefully to prevent mechanical damage.

Faulty Hall Sensors or Encoder Issues

In sensored BLDC motors, Hall sensors or encoders provide rotor position feedback for precise commutation. Faulty sensors can disrupt motor operation.

Causes:

- Electrical Interference: Noise from the ESC or other components can affect sensor signals.

- Physical Damage: Vibration or impact can misalign or damage sensors.

- Aging: Over time, sensors may degrade or fail.

Effects:

- Loss of Synchronization: Causes jerky movements or motor stalls.

- Increased Power Draw: Leads to inefficiency and potential overheating.

Prevention:

- Use shielded cables to minimize electrical interference.

- Securely mount sensors to avoid vibration damage.

- Regularly inspect sensors and replace faulty components.

Electronic Speed Controller (ESC) Failures

The ESC is an essential component of a BLDC motor system, controlling current flow and commutation timing. A malfunctioning ESC can lead to erratic motor performance or complete failure.

Causes:

- Overcurrent: Exceeding the ESC’s rated capacity can damage its components.

- Heat Damage: Inadequate cooling can overheat and destroy electronic components.

- Poor Quality: Low-quality ESCs are prone to failure under high stress.

Effects:

- Motor Misbehavior: Can cause the motor to stutter, lose torque, or overheat.

- Permanent Damage: A faulty ESC can send incorrect signals, potentially damaging the motor.

Prevention:

- Select an ESC with an appropriate current rating for your motor.

- Ensure proper cooling for the ESC.

- Use reputable ESC brands to ensure reliability.

Mechanical Misalignment

Proper alignment between the stator and rotor is critical for efficient motor operation. Misalignment can cause uneven wear, increased noise, and reduced performance.

Causes:

- Improper Assembly: Incorrect installation can misalign components.

- Vibration: Excessive vibration during operation can shift components.

- Wear and Tear: Components may deteriorate or loosen with time.

Effects:

- Increased Friction: Reduces efficiency and accelerates wear.

- Vibrations and Noise: Disrupts smooth operation and damages components.

Prevention:

- Ensure proper alignment during assembly.

- Use anti-vibration mounts to minimize movement.

- Conduct regular inspections and maintenance.

How to Detect and Diagnose Failures

Detecting and diagnosing failures early can prevent costly repairs and downtime. Here are common indicators of motor issues:

- Unusual Noise: Grinding, clicking, or humming noises may indicate bearing or alignment issues.

- Overheating: Excessive heat suggests overloading or insufficient cooling.

- Reduced Performance: Lower torque or speed points to potential winding or magnet issues.

- Jerky Movements: Indicate Hall sensor or ESC malfunctions.

- Burnt Smell or Smoke: Suggests insulation failure or overheating.

Using diagnostic tools like thermal cameras, multimeters, and oscilloscopes can help identify issues more accurately.

Extending the Lifespan of BLDC Motors

To maximize the longevity and reliability of a BLDC motor, consider the following best practices:

- Proper Sizing: Match the motor and ESC to the application load and operating conditions.

- Regular Maintenance: Inspect and maintain bearings, insulation, and connections.

- Cooling Mechanisms: Implement effective cooling solutions to prevent overheating.

- Environmental Protection: Shield the motor from dust, moisture, and contaminants.

- Monitor Performance: Use sensors and monitoring systems to track temperature, load, and speed.

Conclusion

The most common failure in brushless DC motors is overheating, which can lead to winding damage, magnet demagnetization, and other issues. However, other failures, such as insulation breakdown, bearing wear, sensor faults, and ESC malfunctions, can also impact motor performance. You may extend the lifespan and dependability of your BLDC motor by being aware of these failure scenarios, their causes, and preventative strategies. As a reliable BLDC motor manufacturer, Gian Transmission can also help in selecting high-quality motors and ensuring proper guidance for maintaining and optimizing motor performance.