Inrunner Brushless DC Motor

Our inrunner/inner rotor BLDC motors deliver high efficiency and precision, ideal for demanding applications where space is limited. With advanced heat dissipation and durable construction, we provide superior performance and longevity across various sectors.

All of our inner rotor motors are customizable, including:

- Size and Dimensions

- Shaft Configuration

- Winding Configuration

- Voltage

- Power Output

Home / Inrunner Brushless DC Motor

By Structure

- Stator: The stator is stationary and contains the windings. It envelops the rotor.

- Rotor: Inside the stator is where the rotor is found.

- Bearings: Support the rotor for smooth rotation.

- Housing: Protects motor components and often features cooling fins.

- Commutation System: Uses ESC and Hall sensors for speed and direction control.

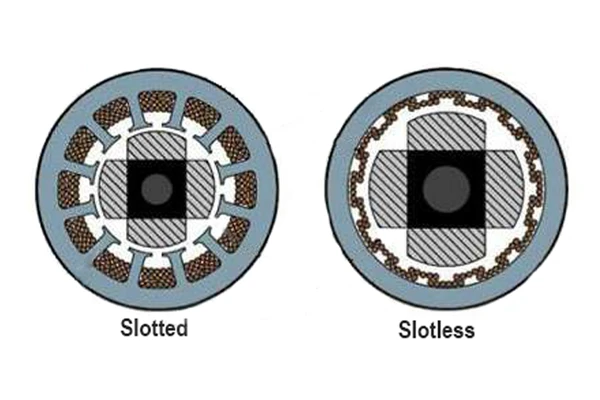

By Rotor Structure

We provide slotless and slotted inrunner BLDC motors designed for high performance, precision control, and versatile industrial applications.

Slotted

- Slotted inrunner BLDC motor uses a stator with slots that house the windings, offering better magnetic coupling and higher torque density.

- Often used in power tools, automotive pumps, and fans.

Slotless

- Slotless inrunner BLDC motor eliminates stator slots, reducing cogging torque and providing ultra-smooth, low-vibration operation ideal for precision applications.

- Often used in medical devices, robotics, and small drones.

By Rotor Magnet Configuration

We provide surface and interior permanent magnet inrunner BLDC motors for optimized torque, efficiency, and dynamic performance across applications.

Surface Permanent Magnet (SPM)

- Magnets positioned on the rotor's outside

- Simple construction, easier to manufacture

- Produces nearly constant air gap flux

- Easier to control with standard BLDC/PMSM drivers

- Used in HVAC, fans, drones, and power tools

Interior Permanent Magnet (IPM)

- Integrated magnets into the rotor core

- Higher production costs and more intricate construction

- Air gap flux varies with rotor position (saliency)

- Complex control algorithms required (usually FOC)

- Better suited for EVs, industrial drives, and servo systems

By Control Method

Our inner rotor brushless DC motor supports sensor-based and sensorless control for precise, efficient performance across dynamic or continuous motion applications.

Sensor-Based (Hall Sensor or Encoder)

- Uses physical sensors to detect rotor position

- Precise position and speed control

- Reliable startup at low or zero speed

- Essential for low-speed or frequent start/stop operations

- Easier implementation of closed-loop control

- Common in robotics, servo systems, and EV traction motors

Sensorless Control

- No physical sensors; Rotor position inferred from back-EMF

- Eliminates need for physical sensors, reducing cost

- Requires motion (typically above 5–10% of rated speed) to operate

- Requires advanced controllers and tuning algorithms

- Ideal for fans, pumps, and applications with continuous motion

From 0 to N - Full Motor Solutions

Featured products

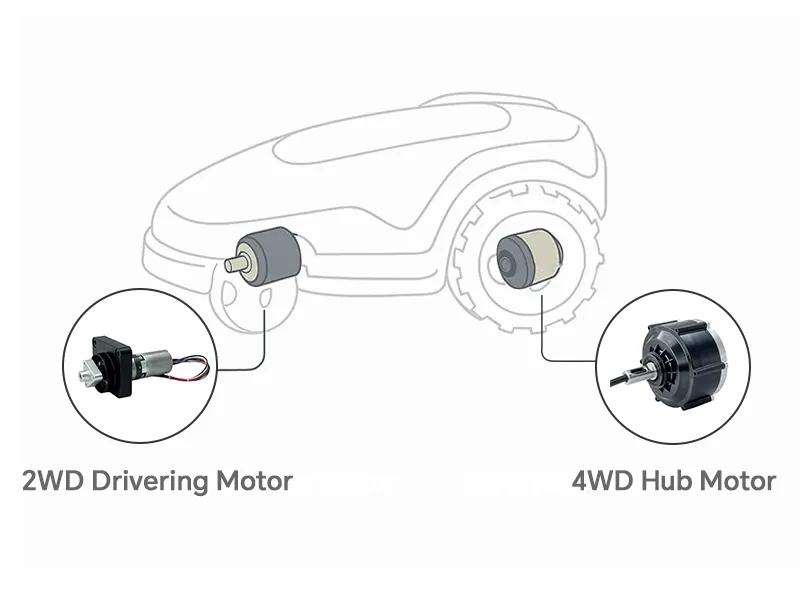

Customer Case

A European manufacturer of smart garden equipment approached us to improve the mobility and terrain adaptability of their next-generation line of robotic lawn mowers.

Their previous motor solution had issues including:

- Inadequate torque when climbing slopes

- Overheating during extended use

- Bulky structure that limited housing design

They needed a high-efficiency, low-profile travel motor that could:

- Handle variable terrain (0–35° slopes)

- Support precise speed control for navigation

- Offer plug-and-play scalability from 2WD to 4WD

Our Solution

- We designed a custom drive motor module featuring:

- Inner rotor brushless DC motor with integrated planetary gearbox

- Voltage: 21.6VDC

- Rated Torque: 2 Nm

- Rated Speed: 49RPM±10%

- Gear Ratio: 1:99.5

Modular Drive System

- 2WD: Two motors mounted on the rear wheels

- 4WD: Four motors mounted independently on each wheel for maximum traction

Results

- Strong power and traction

- better maneuverability

- Adaptability to complex terrain

- Improved work efficiency

Applications

RC Cars

- High-speed capabilities make them ideal for remote-controlled cars requiring quick acceleration.

High-Speed Model Boats

- Suitable for RC boats where high RPM is essential for performance.

Precision Robotics

- Used in applications requiring exact movements and adjustments, such as robotic joints and grippers.

Medical Pumps

- Powers precision pumps used in medical devices for controlled fluid delivery.

Dental Tools

- Ideal for high-speed dental instruments requiring compact and efficient motors.

Aerospace Components

- Utilized in small aerospace applications where high-speed precision is critical.

Laboratory Equipment

- Powers small, high-speed lab instruments requiring consistent and precise operation.

Electric Turbochargers

- Powers small, high-speed turbochargers for improved performance in automotive applications.

FAQ

What are the key benefits of using inrunner brushless DC motors over outrunner brushless DC motors?

Inrunner brushless DC motors offer higher speeds, better heat dissipation, and more compact designs, making them ideal for applications requiring precise control and high RPMs, such as power tools, RC vehicles, and medical devices.

What cooling methods are commonly used in inrunner brushless DC motors?

Response: Common cooling methods include air cooling with heat sinks, forced air cooling, and liquid cooling systems, all of which help manage heat and maintain optimal operating temperatures.

How do inrunner brushless DC motors handle high torque demands?

While inrunners excel in high-speed applications, they can also handle moderate torque demands by optimizing the winding design and using stronger magnets to increase torque output.

What criteria should be addressed while selecting an inrunner brushless DC motor for a certain application?

Key factors include the required speed (RPM), torque, voltage, power rating, cooling requirements, size constraints, and the specific application's operational environment to ensure optimal performance and longevity.

What is the maximum rotational speed (RPM) that an inrunner brushless DC motor can achieve?

The maximum rotational speed of inrunner brushless DC motors can range from 10,000 RPM to over 50,000 RPM, depending on the specific model and application requirements.

What is the typical efficiency range of inrunner brushless DC motors?

Inrunner brushless DC motors typically have an efficiency range of 85% to 95%, making them highly efficient for various high-speed applications.

What are the common voltage ratings for inrunner brushless DC motors?

Common voltage ratings for inrunner brushless DC motors include 12V, 24V, 36V, and 48V, with some industrial models operating at higher voltages.

How much torque can an inrunner brushless DC motor generate?

The torque output of inrunner brushless DC motors can vary widely, from as low as 0.1 Nm for small models to over 5 Nm for larger industrial versions.