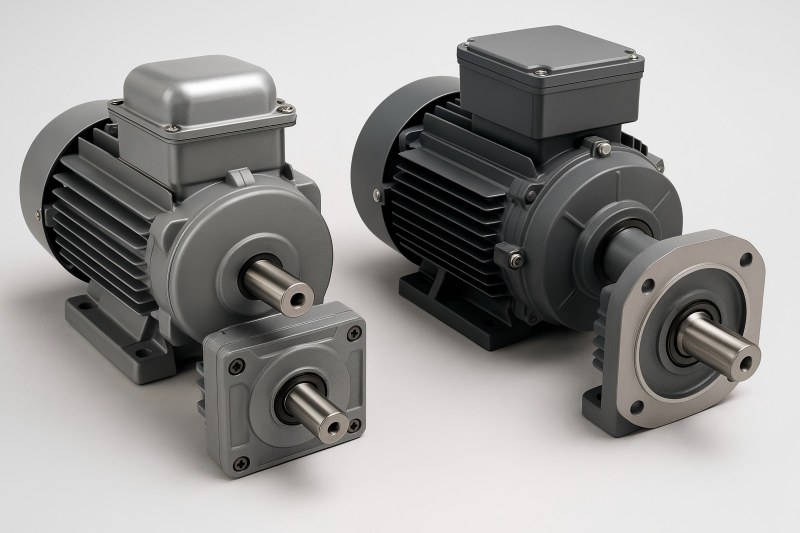

Electric motors are at the heart of countless industrial and commercial applications. When combined with gear systems, they become gear motors, delivering both torque and controlled speed for specific operations. Among the many variations available, single-phase gear motors and three-phase gear motors are the two most widely used categories.

As a manufacturer, we frequently receive questions from clients: Which one should I choose? What’s the difference? Which motor suits my application better?

What’s Gear Motor?

Essentially, a gear motor integrates a gearbox directly into the electric motor. The motor generates power, while the gearbox reduces speed and increases torque to match application demands. Gear motors are essential in industries where controlled speed, high torque, and precision are required, such as conveyor systems, mixers, packaging machines, and lifting equipment.

The difference between single-phase and three phase gear motors primarily stems from their power supply and winding structure, which directly affects performance and usage.

What is a Single Phase Gear Motor?

A single phase gear motor runs on single phase AC power (110V, 220V, or 240V depending on region). This makes them common in residential, light commercial, and small-scale industrial setups.

Key features:

- Designed for low to moderate power requirements.

- Easy to connect since most households and small shops use single phase electricity.

- Typically available in power ratings up to 3 HP (2.2 kW).

- Require starting mechanisms such as capacitors to generate initial torque.

| Cons | Pros |

| Low initial cost | Limited power output |

| Easy to connect (household supply) | Lower efficiency |

| Compact and simple design | Shorter lifespan under heavy loads |

| Best for light-duty applications | Requires starting capacitor |

What is a Three Phase Gear Motor?

A three phase gear motor operates on three phase AC power (380V, 415V, 460V, or higher), which is standard in industrial and manufacturing environments.

Key features:

- Handles higher loads and continuous operation efficiently.

- Commonly used in heavy-duty industries such as steel plants, food processing lines, water treatment facilities, and large conveyors.

- They come in power capacities ranging from fractional horsepower up to several hundred kilowatts.

- Does not require auxiliary starting mechanisms—starts directly with balanced torque.

| Cons | Pros |

| High efficiency and power handling | Higher upfront cost |

| Smooth and reliable operation | Requires 3-phase power supply |

| Longer lifespan in industrial environments | More complex installation |

| Lower operational cost long term |

Construction Differences

| Aspect | Single Phase Gear Motor | Three Phase Gear Motor |

| Power Supply | Single phase (110–240V) | Three phase (380–690V) |

| Starting Mechanism | Needs capacitor or auxiliary winding | Direct start (self-starting) |

| Torque Characteristics | Pulsating torque, less smooth | Continuous torque, smoother |

| Efficiency | Lower, especially at high loads | Higher, very efficient |

| Maintenance | Simpler, fewer components | Requires robust industrial maintenance |

| Cost | Lower upfront | Higher upfront but economical long term |

Performance Comparison

Starting Torque

- Single Phase Gear Motor: Provides decent starting torque with a capacitor but may struggle under heavy loads.

- Three Phase Gear Motor: Delivers strong, reliable starting torque, making it better for heavy machinery.

Running Efficiency

- Single Phase: Efficiency drops significantly at higher loads.

- Three Phase: Maintains high efficiency even at full load, minimizing energy wastage.

Speed Regulation

- Single Phase: More prone to fluctuations and speed drop under load.

- Three Phase: Stable speed performance due to constant torque.

Noise and Vibration

- Single Phase: Slightly noisier with noticeable vibration due to pulsating torque.

- Three Phase: Runs smoother and quieter.

Energy Efficiency and Cost

Single Phase Gear Motor

- Energy efficiency: Inefficient; draws higher energy per unit of work.

- Operational cost: Suitable for applications running only a few hours daily.

- Best for: Small businesses or households with limited budgets.

Three Phase Gear Motor

- Energy efficiency: 15–30% higher than single phase motors at equivalent power.

- Operational cost: Lower in long-term, especially for 24/7 operations.

- Best for: Continuous industrial usage where electricity bills matter.

| Parameter | Single Phase | Three Phase |

| Efficiency Range | 60–75% | 80–95% |

| Power Factor | 0.6–0.8 | 0.8–0.95 |

| Energy Losses | Higher due to phase imbalance | Lower, balanced phases |

| Continuous Duty Performance | Moderate | Excellent |

Application Areas

Single Phase Gear Motor

- Small conveyors

- Packaging machines

- Household equipment (e.g., washing machines, mixers)

- Agricultural pumps for rural households

- Light-duty fans, blowers, and compressors

Three Phase Gear Motor

- Heavy conveyors and material handling

- Industrial mixers and crushers

- Textile machinery

- Elevators, cranes, and hoists

- Large pumps, compressors, and blowers

- Steel, cement, and mining industries

Cost Comparison

| Factor | Single Phase Gear Motor | Three Phase Gear Motor |

| Initial Purchase Price | Lower | Higher |

| Installation | Simple | Requires 3-phase connection |

| Operating Cost | Higher for continuous use | Lower for continuous use |

| Spare Parts | Inexpensive | More robust, slightly costlier |

| Lifetime ROI | Moderate | High |

Example Calculation:

Suppose two motors (2 HP each) run for 2000 hours annually:

- Single-phase efficiency: 80% → consumes ~1,865 kWh/year.

- Three-phase efficiency: 90% → consumes ~1,660 kWh/year.

- At $0.15/kWh, the annual cost difference is ~$30. Over 10 years, that’s $300 in savings, not counting reduced downtime.

Case Study Example

Imagine a small bakery and a large flour mill.

The bakery runs a small conveyor, packaging line, and dough mixer for only 6–8 hours daily. A single phase gear motor is the economical choice since installation and upfront costs are low, and power demands are limited.

The flour mill, on the other hand, runs 24/7 with heavy conveyors, mixers, and bulk handling equipment. A three phase gear motor is essential to reduce downtime, lower electricity bills, and handle the constant heavy loads.

How to Choose the Right Gear Motor

| Question | If Yes → Choose Single-Phase | If Yes → Choose Three-Phase |

| Do you only have single-phase power? | ✅ | ❌ |

| Is your load under 5 HP? | ✅ | ❌ |

| Do you need 24/7 continuous duty? | ❌ | ✅ |

| Is upfront budget your biggest concern? | ✅ | ❌ |

| Do you want lowest lifetime cost? | ❌ | ✅ |

| Industrial or heavy-duty application? | ❌ | ✅ |

The choice between single-phase gear motors and three-phase gear motors is not about which is universally “better,” but about which best fits the application. As a professional gear motor manufacturer, we recognize that single-phase gear motors are cost-effective, accessible, and suitable for small-scale or residential tasks. Three-phase gear motors deliver higher efficiency, reliability, and power for industrial and continuous operations.

In short:

- For home and light-duty machinery, single-phase gear motors are sufficient.

- For factories, construction, and large-scale operations, three-phase gear motors are the clear winner.