DC Gear Motor Manufacturer

Gian uses advanced MIM injection molding to create integrally molded precision gearboxes, offering brushed, brushless, stepper, and servo motor options for diverse application requirements.

Whether you need compact designs, high torque output, or precise motion control, Gian delivers reliable and customizable solutions tailored to your needs.

- Customizable Appearance: size, structure, material

- Flexible Parameters: ratio, speed, voltage

- MES system ensures production traceability

- EPC 200% strict quality inspection

Home / Gear Motor

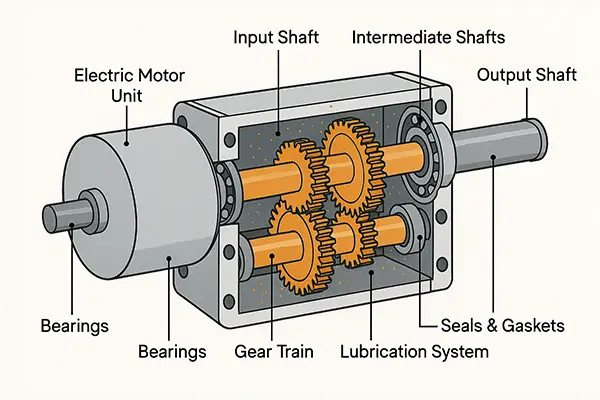

Main Structure of Gear Motor

- Electric Motor: Provides the driving force, can be DC, brushed, or brushless.

- Gearbox Housing: Encloses gears, ensures alignment, protects from dust, and maintains lubrication.

- Input Shaft: Connects motor rotor to gearbox, transferring power into the gear system.

- Gear Train: Transfers torque and speed using spur, planetary, worm, or harmonic gears.

- Output Shaft: Delivers reduced speed, higher torque motion to the external load.

- Bearings: Support shafts, reduce friction, and enhance smooth rotation and durability.

- Seals and Gaskets: Prevent oil leakage and block dust or contaminants entry.

- Mounting Flange/Bracket: Allows secure attachment of the gear motor to machinery.

- Cooling Components: Fins or fans dissipate heat, preventing motor and gear overheating.

What Types of Gear Motors Can We Provide?

We provide four DC gear motor solutions, featuring iron core, coreless, brushed, and brushless technologies, combined with four versatile gearbox types.

Planetary Gear Motor

- Central sun gear, multiple planet gears, outer ring gear.

- High torque density, evenly distributed load.

- 3:1 to >100:1 Speed reduction ratio.

- Commonly used in consumer electronics, medical, and automobiles.

Spur Gear Motor

- Simple parallel shaft gears.

- Moderate torque capacity.

- 3:1 to ~10:1 per stage.

- Apply for consumer electronics, low-cost automation, pumps, mixers.

Worm Gear Motor

- Screw-like worm driving a worm wheel.

- Very high torque, excellent load holding.

- 10:1 to 80:1 in a single stage.

- Apply for lifts, hoists, gates, conveyors.

Harmonic Gear Motor

- Employs flexible spline, circular spline, and wave generator components.

- High torque-to-weight ratio.

- 30:1 to 320:1 in compact form.

- Apply for robotics, aerospace, precision positioning.

From 0 to N - Full Motor Solutions

What Can Our Gear Motors be Customized?

Brushed iron core motor: The lowest cost option, durability can be improved through reasonable component design. Typically used in motors with frame diameters greater than 8 mm.

Brushless iron core motor: Needs special drive circuit and three-phase controller, highly wear-resistant. Offers superior torque density in compact sizes, mainly used in motors exceeding 12mm frame diameter.

Brushless coreless motor: Coreless design ensures ultra-low rotor inertia, smooth operation, and zero cogging. Delivers fast response and high efficiency, ideal for precision, small motors demanding rapid responsiveness in advanced applications.

Semi-Enclosed Frame Design: Offers partial shielding, leaving certain areas ventilated for airflow and cooling.

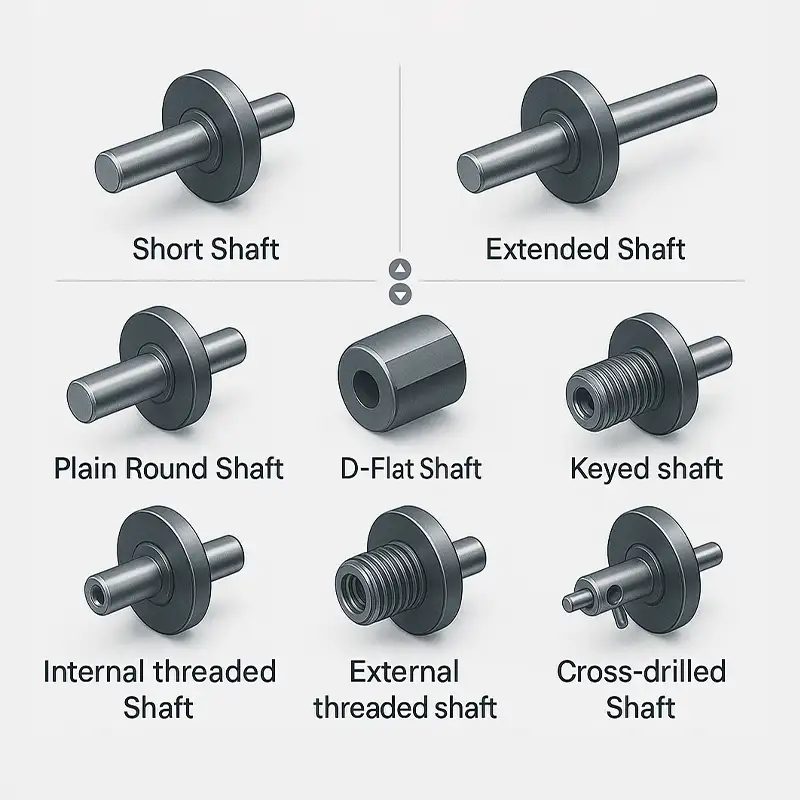

- Short Shaft: Compact designs for limited installation space or direct coupling.

- Extended Shaft: Provides flexibility for mounting pulleys, gears, couplers, or encoders.

- Plain Round Shaft: Smooth cylindrical shaft, sometimes with a flat cut (D-shaft) for slip-free coupling.

- D-Cut Shaft (D-Flat): One side flattened to ensure secure fit with gears, pulleys, or set-screws.

- Keyed Shaft: Slot (keyway) cut along the shaft for use with a matching key in couplers or gears to prevent slipping.

- Internal Threaded Shaft (Tapped Hole): Allows fastening components directly with a screw or bolt into the shaft.

- External Threaded Shaft: Shaft end machined with threads for nut-fastened connections.

- Cross-Drilled Shaft: Hole drilled through shaft for pin connections, commonly seen in robotics or light couplings.

Metal Gearbox: High strength handles heavy loads and torque without deformation, offering long life, wear resistance, and reliable performance in high-temperature demanding environments.

Plastic Gearbox: For geared motors with a diameter less than 10 mm, metal gears are very expensive, so we use gears made of MIM injection-molded engineering plastics.

What Can Gear Motor be Integrated with?

Sensors

- Position sensors, encoders, Hall sensors, temperature sensors options.

- Enable feedback for speed, position, and load control.

Controllers

- PWM controllers, motor drivers, PLCs, microcontrollers.

- Regulate motor behavior, automate tasks, enable programmable motion.

Communication Interfaces

- CAN, RS485, Modbus, EtherCAT.

- Integrate gear motors into smart systems or IoT networks.

Mechanical Assemblies

- Lead screws, pulleys, cams, linkages, robotic joints.

- Translate rotary motion into linear or complex mechanical actions.

Brakes and Clutches

- Electromagnetic or mechanical brakes hold position when power is off.

- Allow safe stopping, holding, or controlled motion disengagement.

GIAN Production Process

Gearbox Machine Dispensing

- Automated machines dispense lubricant precisely, ensuring alignment, smooth rotation, reduced wear, and consistent gear motor performance.

🔩 Output Shaft Installation

- High-precision output shaft installation ensures proper gear alignment, accurate torque transmission, and minimal operational backlash.

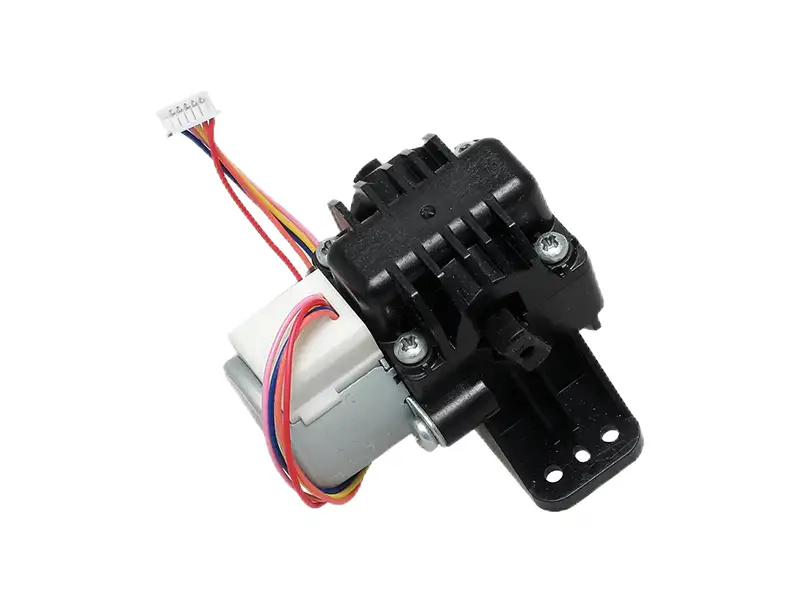

🧰 Manual Assembly of Gearbox and Motor

- Trained technicians manually align and combine the motor with the prepared gearbox housing, ensuring proper mechanical fit and compatibility.

🧷 Fixing and Fastening

- All components are securely fastened using torque-calibrated tools to prevent vibration, loosening, or misalignment during operation.

🖥️ MES System Entry

- Each unit is scanned and recorded into our MES, enabling full traceability, real-time monitoring, and production data tracking.

🏠 Housing Installation

- Manual installation includes protective shell, reinforcement, and wiring, safeguarding internal components from dust, impact.

⚙️ Performance Testing

- Each gear motor undergoes rigorous testing to confirm: Gear ratio accuracy, Rotational speed and torque output.

🔊 Noise and Vibration Testing

- We test every unit for noise level and vibration using calibrated equipment to ensure it operates smoothly and quietly.

✅ EPC 200% Inspection

- Undergoes EPC 200% quality inspection(auto parts), including both functional and visual checks, to guarantee zero-defect output.

📦 Packaging

- Approved gear motors are packed with anti-static, shock-resistant materials and labeled for secure delivery, storage, traceability, and logistics.

What We Offer to Empower Your Device?

Featured Products

Gian TR039-P01 Planetary Gear Motor

- Rated Voltage: 12V

- No-load Speed: 255±2 5.5RPM

- Locked-rotor Current: ≤15A

Gian TR048-P01 Planetary Gear Motor

- Rated Voltage: 24V

- Rated Speed: 185RPM

- Electric Current: <2A

Gian TR095-P01 Spur Gear Motor

- Rated Voltage: 12V

- Rated Current: 0.35A Max

- Rated Speed: 100±12%RPM

.jpg)

Gian YF003-P01 Spur Gear Motor

- Rated Voltage: 4-8.4V

- No-load Speed: 0.133 sec/ 60°(75RPM)

- No-load Current: 950mA

Applications

Automotive

We offer OEMs and Tier 1 suppliers high-performance, compact motor solutions engineered for automotive innovation. Our products are built to meet rigorous industry standards and customized to integrate seamlessly into modern vehicle systems.

Armrest Lock Actuation

- Our gear motors ensure quiet, compact, and reliable actuation for car armrest locks, enhancing passenger comfort and overall interior functionality.

Laser Projector Screen Rotation

- We provide precision gear motors for infotainment systems, enabling stable, low-backlash laser screen rotation for dynamic, responsive user interfaces.

Electric Console Lock Systems

- Used for secure electric center console locking, with strong build and optional feedback ensuring reliable performance in all operating conditions.

Smart Home

We provide compact, efficient, and reliable motor solutions tailored for smart home appliances, enhancing automation and user convenience.

Coffee Machine Nozzle Rotation Drive Motor

- Compact DC gear motor controls nozzle rotation with precision, ensuring stable torque, quiet operation, and repeatable positioning for beverage dispensing systems.

Mowing Robot Blade Motor

- High-torque sealed gear motors ensure smooth torque delivery, continuous-duty performance, and terrain adaptability for robotic lawn mowers in outdoor environments.

Vacuum Cleaner Roller Motor

- High-RPM gear motor with optimized ratios drives roller brushes, ensuring stable speed, efficiency, and strong surface contact for effective cleaning.

Industrial Control

Gear motors integrate motor and gearbox, providing controlled speed and amplified torque. Widely used in industrial control for automation, precision positioning, and reliable power transmission across diverse machinery applications.

Spur Gear Motor

- Spur gear motors provide efficient torque transmission, precise speed control, and reliability, enabling AGV vehicles to achieve smooth navigation, load handling, and consistent performance.

Infrared Thermal Imaging Gear Motor

- Infrared thermal imaging gear motors enable precise camera positioning, ensuring reliable night vision, accurate tracking, and enhanced security monitoring in low-light or obscured environments.

Pitch Gear Motor

- Pitch gear motors enable precise camera angle adjustments, ensuring stable, accurate positioning for security monitoring systems with reliable torque and smooth, controlled movement.

Robotics

Gear motors in robotics provide precise motion control, torque amplification, and speed reduction, enabling stable movement, accurate positioning, and efficient power transmission for robotic arms, joints, and mobile platforms.

Planetary Gear Motor

- Planetary gear motors deliver compact design, high torque density, and precise speed control, enabling robots to achieve stable movement, efficient power transmission, and accurate positioning.

Harmonic Gear Motor

- Harmonic gear motors deliver high torque, zero backlash, and compact design, enabling precise, smooth, and efficient motion control in robotic arms, joints, and advanced automation.

Brushless Gear Motor

- Brushless gear motors power robotic transport vehicles with high efficiency, low noise, and reliable torque, ensuring smooth movement, precise control, and extended operational lifespan.