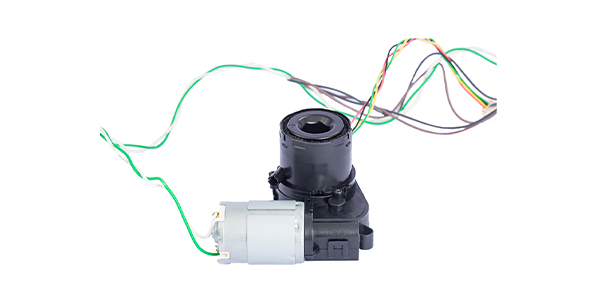

Worm Gear Motor Supplier

We design and manufacture AC and DC worm gear motors in a wide range of sizes. Whether it is high torque transmission, compact design or self-locking ability, we can provide unmatched motor solutions for your equipment.

In addition to standard gear worm motor, we can also provide you with customized alternatives:

- Shaft Configuration: Single or dual output shaft

- Mounting Options: Flange or base mount configuration

- Gear Ratio Selection: Gear ratio variations

- Enclosure Rating: Choose from different IP ratings for different environmental conditions

- Accessories: Encoder, brake or thermal protector

Home / Worm Gear Motor

By Structure

Our worm gear motor features a worm shaft, worm wheel, motor, housing, bearings, output shaft, lubrication system, and versatile mounting options.

- Worm Shaft: A screw-like shaft connected to the motor.

- Worm Wheel (Gear): A helical gear meshing with the worm shaft.

- Electric Motor: Usually AC, DC, or servo motor driving the worm shaft.

- Gear Housing: Encloses and supports the worm gear mechanism.

- Bearings: Support shafts and reduce friction during rotation.

- Output Shaft: Transfers the reduced-speed, high-torque motion to the load.

- Lubrication System: Ensures smooth operation and reduces gear wear.

- Mounting Interface: Flange, foot, or shaft mounting for installation.

By Input Type

Our worm gear motor supports AC or DC input, offering flexible voltage, torque, and control for varied industrial and mobile applications.

DC

- DC worm gear motor runs on 12V–48V battery or DC power supply.

- Generally provides high starting torque.

- Easy to control speed&direction through voltage variation or pulse-width modulation (PWM).

- Worm drive DC motors need regular maintenance, especially brush replacement in brushed types.

AC

- AC worm gear motor runs on mains AC power like 110V or 220V.

- Requires more complex control systems like variable frequency drives (VFD) to adjust speed.

- Provides consistent torque, suitable for continuous operation.

- In general, less upkeep is required than with brushed DC motors.

By Motor Type

We offer design brushed, brushless, stepper, and servo motor types for tailored torque, control precision, and application versatility.

Brushed DC Motor

- Simple design with mechanical brushes and commutator

- Moderate torque with simple speed reduction

- Simple PWM or analog control

- Ideal for toys, actuators, small automation

Brushless DC (BLDC) Motor

- Electronic commutation for longer motor life

- High efficiency and low maintenance

- Quiet operation with less heat generation

- Ideal for Robotics, conveyors, medical devices

Stepper Motor

- Precise incremental motion without feedback

- High holding torque at standstill

- High holding torque via worm gear self-locking

- Easy integration into step-based automation

Servo Motor

- Closed-loop control with encoder feedback

- Accurate positioning, speed, and torque control

- Feedback-enabled high dynamic response

- Ideal for robotics, CNC, and demanding motion control

From 0 to N - Full Motor Solutions

By Material

Our worm gear motor uses hardened steel, bronze, and aluminum alloy for strength, wear resistance, corrosion protection, and lightweight performance.

Worm (Screw) Material

- Hardened Steel: Offers high strength and durability; used in industrial-grade motors.

- Alloy Steel: Often heat-treated for better wear resistance and toughness.

- Stainless Steel: Applied in food-grade and corrosion-resistant use cases.

Worm Gearbox Material

- Bronze: Commonly used; low friction and wear-resistant against steel worm.

- Brass: Used in small or light-duty applications for cost savings.

- Plastic (Nylon or POM): Found in low-load, quiet-running, or lightweight devices.

Housing Material

- Aluminum Alloy: Lightweight and corrosion-resistant, ideal for general-purpose and portable applications.

- Cast Iron: Strong and vibration-resistant; used in heavy-duty, industrial environments.

- Steel: High durability but heavier; used where structural strength is critical.

What Control Systems can be Combined with?

VFD (Variable Frequency Drive)

- For AC worm gear motors

- Varies input frequency to control motor speed, torque.

- Enables soft start, overload protection & reverse control.

PWM Controller (Pulse Width Modulation)

- For DC worm gear motors

- Modulates voltage to control speed efficiently.

- Ensures smooth and energy-efficient operation.

PLC (Programmable Logic Controller)

- Sequences motor actions, starts/stops, speed control, logic-based operations.

- Ideal for industrial automation with sensors and timers.

Microcontroller

- Controls worm gear motors in compact, cost-sensitive, or custom setups.

- Supports H-bridge, PWM, and sensor feedback integration.

Encoders (Incremental or Absolute)

- Provide position and speed data for precise motion control.

- Common in servo + worm gear motor systems.

Limit Switches

- Define motion boundaries, prevent overtravel.

- Used for homing, safety stops, and mechanical end detection.

Applications

Elevators and Lifts

- Provides torque and control for smooth vertical movement, handling passengers and cargo. The self-locking function prevents free fall during power or mechanical failure, ensuring safety.

Food Processing Equipment

- Worm gear motors power mixers, grinders, conveyors, and packaging machines, providing torque and precise control for efficient, reliable food processing.

Beverage Dispensing Systems

- Worm drive electric motors drive pumps and dispensers in beverage machines, fitting into limited spaces to ensure smooth, accurate dispensing with consistent flow rates and portion sizes.

Stage Lifts

- Worm drive gear motor power stage lifts, mobile stages, platforms, and props in theaters and concert venues, meeting the demands of live performances.

Concrete Mixers

- The motor powers the concrete mixer's drum, ensuring thorough mixing with necessary torque and speed. Reliable operation guarantees a uniform mix, crucial for concrete quality.

Projector Lifts

- Providing precise height control and stability, the self-locking feature prevents shifting. Smooth, quiet operation ensures a professional, distraction-free environment.

FAQ

What effect does a worm gear motor's gear ratio have on its operation?

A higher gear ratio increases torque and reduces speed, ideal for high-torque, precise control applications. Reduced gear ratios result in more speed but reduced torque.

What is the function of the worm motor gear in a worm gear motor?

The worm motor gear transmits power from the motor to the worm wheel, reducing speed and increasing torque for efficient and precise motion control.

What distinguishes a helical worm gear motor from other gear motor types?

A helical worm gear motor combines efficient helical gears with self-locking worm gears for smooth, quiet operation and high torque, ideal for precise positioning and high reduction ratios.

How does a high torque worm gear motor benefit industrial applications?

A high torque worm gear motor ensures robust power transmission and reliability, ideal for heavy-duty industrial machinery and automation systems requiring strong torque and precise control.