Modern lawn mowing robots, CNC machines, and agricultural harvesters all share a common performance foundation — precise, efficient, and consistent cutting systems. At the heart of these systems lies the motor — the driving force that turns mechanical components into synchronized, high-speed cutting machines.

Introduction: Why Precision Cutting Matters

Precision cutting defines quality, speed, and cost-efficiency across industries. Whether trimming grass with a robotic mower, slicing composite materials in a CNC machine, or processing crops, the motor-blade interaction determines how smoothly and accurately material is cut.

Traditional mechanical systems relied on belt-driven motors or combustion engines that lacked fine control. Modern systems instead employ electronic motor control, using feedback loops and digital algorithms to precisely manage torque, speed, and position.

As automation and robotics evolve, precision cutting becomes less about mechanical power and more about control intelligence — and that is where motors truly shine.

The Core Role of Motors in Blade Control Systems

Power Conversion and Torque Delivery

Electric motor for mower robot transforms electrical energy into rotation, driving the blade efficiently. In a precision cutting context, power alone is not enough — the motor must deliver torque consistently, even under variable loads.

For example:

- In robotic lawn mowers, blade torque must adjust dynamically when grass density changes.

- In CNC routers, speed stability is critical to prevent tool chatter or surface imperfections.

These systems typically use BLDC or PMSM motors for superior efficiency, control precision, and durability.

| Motor Type | Typical Use Case | Speed Range (RPM) | Torque Control | Efficiency (%) |

| Brushed DC | Simple trimmers, small devices | 1,000–4,000 | Moderate | 70–80 |

| BLDC | Lawn mowing robots, CNC cutting | 3,000–10,000 | Excellent | 85–95 |

| PMSM | Industrial precision cutters | 1,000–8,000 | Excellent | 90–96 |

| Stepper Motor | Micro-blade positioning | 0–1,000 | High positional accuracy | 75–85 |

Blade Control: From Motor to Motion

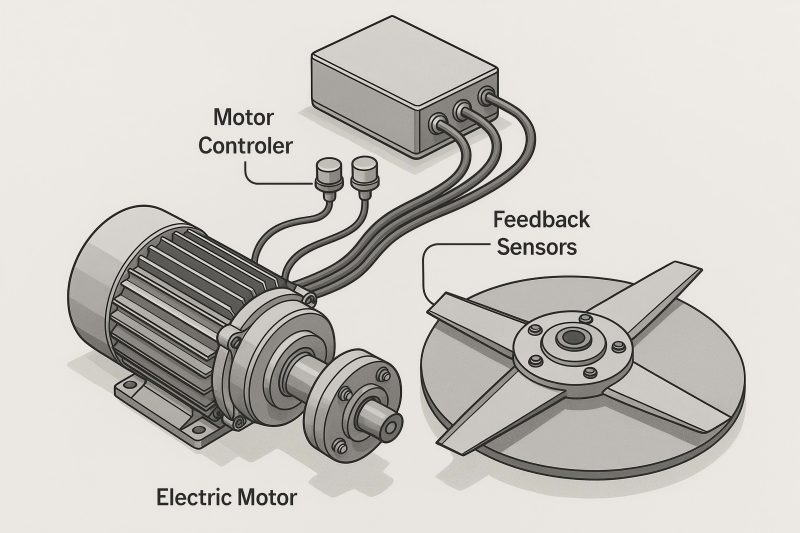

The Motor-Blade Connection

In a precision cutting system, the blade is mounted directly or indirectly to the motor shaft. The mounting interface — often a hub or coupling — must minimize vibration and maintain concentric alignment to prevent uneven cutting.

High-end systems use:

- Dynamic balancing for the rotor-blade assembly.

- Vibration-absorbing mounts to reduce resonance.

- Magnetic or direct-drive couplings for torque transfer with minimal mechanical wear.

Torque, Speed, and Stability

Three core parameters govern motor performance in cutting applications:

- Torque (N·m): Determines cutting force and penetration depth.

- Speed (RPM): Controls the blade tip velocity and affects surface smoothness.

- Stability (ΔRPM): Ensures the motor maintains constant speed despite resistance.

Maintaining these variables within tight tolerances is essential for consistent cutting depth and edge smoothness.

Feedback and Sensor Systems

A true precision cutting motor doesn’t just spin — it thinks.

Sensors give real-time feedback, enabling instant motor controller adjustments to voltage, current, and phase.

Common feedback sensors include:

- Hall sensors: Detect rotor position for commutation.

- Encoders: Measure angular displacement or speed.

- Current sensors: Monitor load changes.

- Temperature sensors: Prevent overheating.

These components form a closed-loop system that continually fine-tunes motor output for precise cutting.

Control Strategies for Precision Cutting

PID and FOC Control

The most common control algorithms include:

- PID (Proportional-Integral-Derivative) Control: Maintains constant speed by correcting error between actual and target RPM.

- FOC (Field-Oriented Control): A vector control technique used in BLDC and PMSM motors for fine torque and speed regulation.

FOC allows independent control of torque and flux, resulting in smooth rotation, reduced noise, and precise cutting force — ideal for autonomous cutting applications like robotic mowers and food slicers.

Adaptive Load Control

Advanced controllers use load-adaptive algorithms that increase torque or speed based on detected resistance. For instance:

- When a lawn mower encounters thick grass, motor current rises.

- The controller instantly boosts voltage to maintain RPM.

- Once resistance drops, power output reduces to save energy.

This adaptability not only improves performance but also extends battery life and reduces mechanical wear.

Motor Selection for Blade Control Systems

Choosing the right motor depends on application demands, such as cutting hardness, precision level, and operating environment.

| Parameter | Light-Duty Cutting (e.g., lawn robots) | Medium-Duty Cutting (e.g., trimmers) | Heavy-Duty Cutting (e.g., CNC, industrial saws) |

| Motor Type | BLDC | BLDC / PMSM | PMSM / Servo Motor |

| Power Range | 50–200 W | 200–500 W | 1–5 kW |

| Torque | 0.2–0.8 N·m | 0.5–2.0 N·m | 3–15 N·m |

| Speed | 3,000–6,000 RPM | 4,000–8,000 RPM | 1,500–5,000 RPM |

| Cooling | Passive | Forced air | Liquid or fan-assisted |

| Control System | PWM | PID | FOC / Servo Feedback |

For lawn mowing robots, compact, energy-efficient BLDC motors are preferred due to their low noise, smooth torque curve, and integration with smart controllers.

Case Study: Motor Control in Robotic Lawn Mowers

Robotic mowers rely on their cutting motors to deliver consistent grass trimming, even under unpredictable outdoor conditions.

Typical configuration:

- Power supply: 24 V DC battery

- Cutting speed: 3,000–5,000 RPM

- Torque: 0.3–0.6 N·m

- Controller: Sensor-based BLDC driver with FOC algorithm

- Protection: Overcurrent, stall, and thermal shutdown

Process workflow:

- Startup: The controller accelerates the motor to target speed gradually to avoid jerks.

- Operation: Speed feedback from Hall sensors ensures constant RPM despite variable grass load.

- Adaptive mode: If blade speed drops >10%, controller increases duty cycle to restore speed.

- Safety mode: Motor stops immediately if lift or tilt sensors trigger.

This multi-stage control ensures uniform grass cutting, minimal noise, and high safety.

Vibration, Noise, and Balance Optimization

One of the biggest challenges in blade motor systems is vibration. Excessive vibration causes:

- Poor cutting precision

- Bearing damage

- Noise increase

- Structural fatigue

To counter this, manufacturers employ:

- Dynamic balancing of the blade assembly

- Anti-vibration motor mounts

- Rotor balancing rings

- Soft-start algorithms to avoid sudden torque spikes

The result is a smoother, quieter operation — crucial for residential robotic lawn mowers that often run during the night.

Safety Features in Blade Motor Systems

Safety is non-negotiable in cutting applications. Modern motor controllers incorporate multi-layer protection, including:

- Overcurrent protection: Cuts off power if torque exceeds design limits.

- Thermal cutoff: Shuts down motor when winding temperature exceeds threshold.

- Tilt/lift detection: Stops blades if mower is lifted or flipped.

- Soft braking: Gradually halts rotation to avoid abrupt stress on blades.

- Sensor redundancy: Dual Hall or encoder systems for fault tolerance.

These ensure operational reliability and compliance with safety standards like IEC 60335 for domestic appliances.

Material and Mechanical Design Impact

Even with advanced motors, blade control precision depends on mechanical design:

- Blade geometry: Determines cutting efficiency and required torque.

- Shaft alignment: Reduces radial load and vibration.

- Bearing selection: Sealed ball bearings minimize friction.

- Housing materials: Aluminum or polymer composites for thermal management and noise damping.

Combining these factors with smart motor control yields both durability and cutting precision.

Energy Efficiency and Thermal Management

Efficiency is a top priority in battery-powered and long-duration systems.

Energy losses arise from:

- Motor copper and iron losses

- Friction and air drag

- Inefficient speed control

Solutions include:

- High-efficiency BLDC designs (with ≥90% efficiency).

- PWM optimization to minimize switching losses.

- MOSFET-based controllers for low heat generation.

- Passive or fan-assisted cooling around motor housing.

A 10% gain in motor efficiency can extend operational time by up to 20–25%, especially valuable for autonomous lawn mowers.

Integration with Smart Control Platforms

With the rise of IoT and AI-driven equipment, motors are no longer isolated components. They’re part of smart cutting ecosystems.

Modern systems integrate with:

- CAN-Bus / RS-485 communication for coordinated control between drive and cutting motors.

- AI-based adaptive load analysis to predict torque demand.

- Edge computing controllers that analyze vibration and current data in real time.

These advancements push the precision and efficiency of cutting systems to new heights.

Comparative Example: Precision Motor Performance Metrics

| Feature | Standard DC Motor | Precision BLDC Motor with FOC |

| Torque Ripple | High | Very Low |

| Speed Stability | ±10% | ±1% |

| Noise Level | 70 dB | 50 dB |

| Energy Efficiency | 75% | 90% |

| Service Life | ~3,000 h | 10,000 h+ |

| Control Accuracy | Limited | High (feedback controlled) |

The improvement in motor control translates directly to cutting uniformity, durability, and safety.

Future Trends in Blade Control Motors

Integrated Sensorless Control:

Using back-EMF detection to reduce cost and simplify wiring.

AI-Enhanced Predictive Maintenance:

Monitoring vibration and current patterns to detect bearing wear or blade imbalance before failure.

High-Efficiency Magnetic Materials:

Adoption of amorphous or nanocrystalline cores to reduce losses.

Lightweight Composite Housings:

Improving cooling and reducing acoustic resonance.

Wireless Power Transfer:

Emerging in cordless systems to eliminate mechanical connectors entirely.

These innovations will make blade control motors smarter, lighter, and longer-lasting — the foundation of next-generation precision cutting.

Motors are far more than power sources; they are the brains and muscles of every precision cutting system. From maintaining constant RPM under variable loads to adjusting torque for different materials, they ensure smooth, accurate, and efficient cutting.

Modern BLDC and PMSM motors, paired with intelligent control systems, deliver the balance of power, precision, and protection required for applications ranging from robotic lawn mowers to industrial CNC machines.

As technologies like AI, IoT, and advanced materials continue to evolve, the next generation of blade control systems will redefine what precision cutting means — achieving millimeter-level accuracy with whisper-quiet, energy-optimized, and fully autonomous operation.