PM Stepper Motor Supplier

Our permanent magnet stepper motors are mostly 2-phase in sizes ranging from 20 to 86 mm, and the step angle is 3.75°,7.5°, 15° or 18°. And provide precise control, high reliability, low maintenance and energy efficiency, compatibility with various control systems for versatile applications.

By offering these customizable options, we meet a wide range of customer needs and increase the usability in different applications:

- Customization Options

- Custom Windings

- Shaft Modifications

- Mounting Configurations

- Connector Options

Home / Permanent Magnet Stepper Motor

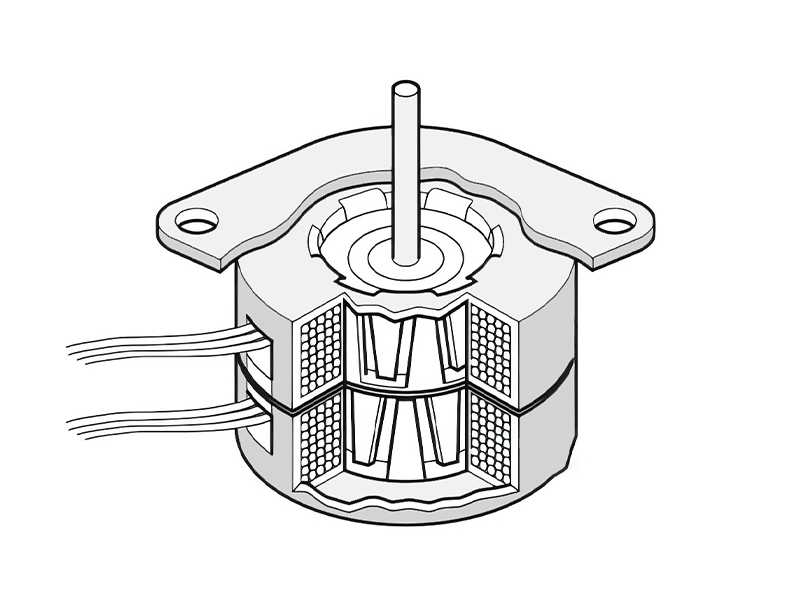

PM STEPPER MOTOR COMPONENT

This overview offers a comprehensive understanding of Permanent Magnet motors and their components. For more details on any specific part or type of PM motor, feel free to ask!

- Stator: Magnetic fields are produced by windings, and a spinning magnetic field is produced by pole pairs.

- Rotor: Permanent magnets on the rotor interact with stator fields, supported by a core.

- Shaft: The central axis that connects the rotor to the external mechanical load.

- Bearings: Support the shaft, allowing smooth and stable rotation.

- Housing: Encases and protects the internal components from dust, debris, and damage.

- End Bells/Caps: Attached to housing ends, containing bearings and providing structural support.

- Terminal or Connector: The interface for electrical connections to the windings.

Featured products

By Rotor and Stator Structure

With a permanent magnet rotor and a laminated stator with coils, our PM stepper motor ensures accurate step movement and small size.

Standard PM Stepper Motor

- Uses cylindrical permanent magnets in the rotor; Stator has salient poles with coils

- Laminated stator, simple structure

- Typically 7.5°–15°

- Used for Small printers, basic robotics, indicators, toys

Can-stack PM Stepper Motor

- Rotor made of a radial ring magnet; stator has pressed steel laminations ("can" structure)

- Usually 7.5°–18°

- Often used in small-diameter forms (e.g., 15–35 mm)

- Used for HVAC controls, dashboard instruments, low-power valve actuators, vending machines

Disk Magnet PM Stepper Motor

- Thin disk-shaped rotor with axial magnetization; stator surrounds rotor disk

- Can go down to 3.75° or finer

- Ultra-thin, space-saving

- Medical devices, camera control, aerospace, precision optics

By Drive Method

Our PM stepper motor supports full-step, half-step, and microstepping drive methods for adaptable torque, resolution, and motion smoothness.

Full-step Drive

- Energizes two phases at once (or one, depending on the mode)

- Moves one full step per input pulse

- Produces maximum torque per step

- Step angle typically equals motor's rated step angle (e.g., 7.5°, 15°)

- Ideal for Printers, basic automation arms, simple indexing systems

Half-step Drive

- Alternates between energizing one and two phases

- Moves half a step per input pulse

- Doubles the resolution e.g., 7.5° becomes 3.75°

- Smoother motion with reduced resonance

- Ideal for Scanners, vending mechanisms, 2D plotters

Microstepping Drive

- Divides each full step into many microsteps (e.g., 8, 16, 32 steps)

- Uses precise current control through sine/cosine waveforms

- Achieves very smooth and quiet motion

- Slight torque reduction at extreme microsteps

- Ideal for high-precision applications like CNC, 3D printers, and robotics

From 0 to N - Full Motor Solutions

By Mounting Style

Our PM stepper motors offer PCB-mount and frame-mount styles for easy integration in compact electronics or robust industrial applications.

PCB-mount

- Designed to mount directly onto printed circuit boards (PCBs).

- Extremely compact and lightweight.

- Simplifies integration into electronic assemblies.

- Typically used in Camera modules, optical drives, portable medical devices, handheld instruments

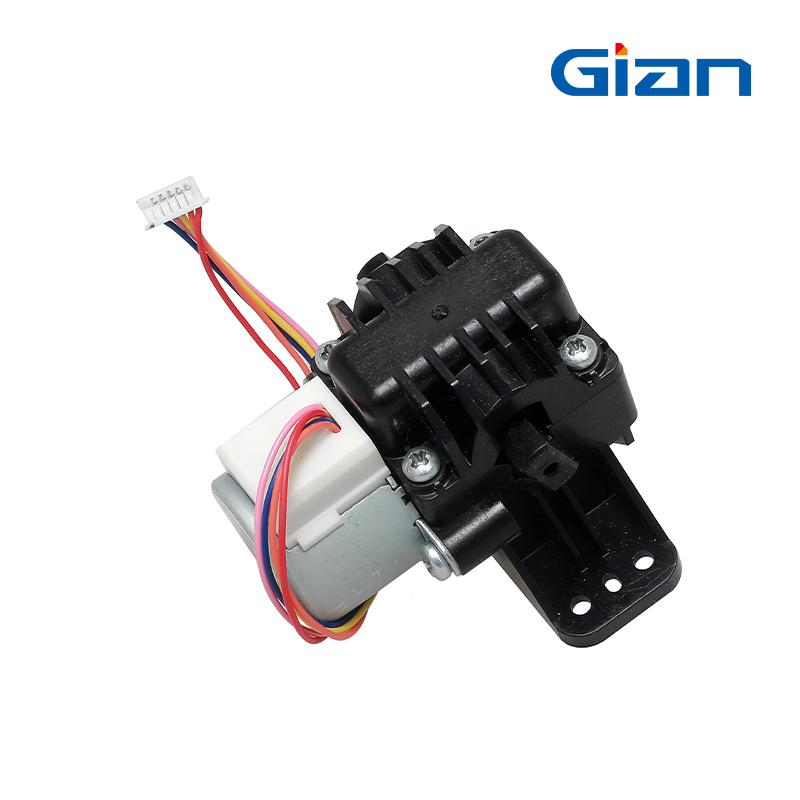

Frame-mount

- Comes with a standardized housing (e.g., NEMA frame sizes).

- Higher torque output and mechanical durability.

- Suitable for standalone mounting or machine frames.

- Used for Industrial automation, label printers, ticket dispensers, HVAC control systems.

By Control Methods

We can provide open-loop, closed-loop, and current control methods for PM stepper motors, ensuring cost efficiency, precision, and stable torque.

Open-Loop Control

- Easy and economical to use, providing cost-effective and user-friendly solutions.

- Perfect for applications where precision is not necessary.

- Commonly used in printers, basic CNC machines, and simple automation tasks.

Closed-Loop Control

- Improves reliability and accuracy.

- Compensates for steps missed or external disturbances.

- Utilizes encoders or resolvers for feedback.

- Used in high-precision applications like robotics and advanced CNC machines.

Current Control

- Ensures consistent torque regardless of speed variations.

- Prevents motor overheating by limiting current.

- Used in applications where maintaining constant torque is crucial.

Applications

Printers and Scanners: PM stepper motors are commonly used in printers and scanners for positioning the print head and moving paper.

Small Robotics: Due to their cost-effectiveness and sufficient torque at low speeds, PM stepper motors are often used in small robotic applications and hobby projects.

Security Cameras: They are used in pan and tilt mechanisms for security cameras to provide smooth and precise movement.

Automotive Instrumentation: PM stepper motors can be found in automotive dashboards for gauge control and needle positioning.

Textile Machinery: PM stepper motors are utilized in textile machinery to provide precise control over thread and fabric movement.

Vending Machines: PM stepper motors are used to control the dispensing mechanisms in vending machines.

FAQ

Can a PM stepper motor be used for continuous rotation?

Yes, a PM stepper motor can be used for continuous rotation by continuously sending pulses to the motor driver. However, stepper motors are typically used for applications requiring precise control of position and speed rather than high-speed continuous rotation.

How do I select the appropriate PM stepper motor for my industry?

Choosing the right PM stepper motor involves considering factors such as the required torque, step angle, speed, voltage, and current ratings, as well as the specific requirements of your application.

Are high speeds possible for PM stepper motors?

PM stepper motors are generally more efficient at lower speeds. While they can run at higher speeds, their performance and torque may decrease compared to hybrid stepper motors.

Are PM stepper motors suitable for precise positioning applications?

Yes, PM stepper motors are suitable for applications requiring precise positioning, especially when high precision and fine resolution are not critical.

How does the operation of a permanent magnet stepper motor differ from a variable reluctance stepper motor?

A permanent magnet stepper motor uses a magnet rotor for higher low-speed torque, while a variable reluctance motor has a soft iron rotor without magnets.

How can a permanent magnet stepper motor's performance be maximized?

Optimize performance by matching the motor with a precise current control driver, selecting correct microstepping settings, ensuring proper alignment, and minimizing friction and load inertia.