Electric motors drive modern automation, powering applications from robotics and conveyors to drones and electric vehicles. However, motors cannot operate in isolation—they require precise electronics to control their performance. This is where motor drivers and motor controllers come into play.

Though often used interchangeably, these two components serve distinct yet complementary roles in motor operation. As a motor systems manufacturer, understanding the differences between motor drivers and motor controllers is critical for proper system design, cost optimization, and application-specific performance.

What is Motor Control?

Before diving into the distinctions, it’s important to understand the broader concept of motor control. Motors require regulated electrical signals to operate at desired speeds, torques, and directions. These signals must be dynamically adjusted based on feedback, load conditions, or programmed logic.

This control process is achieved using:

- Motor Controllers – the brain of the operation

- Motor Drivers – the muscle that executes instructions

Both are essential in electromechanical systems.

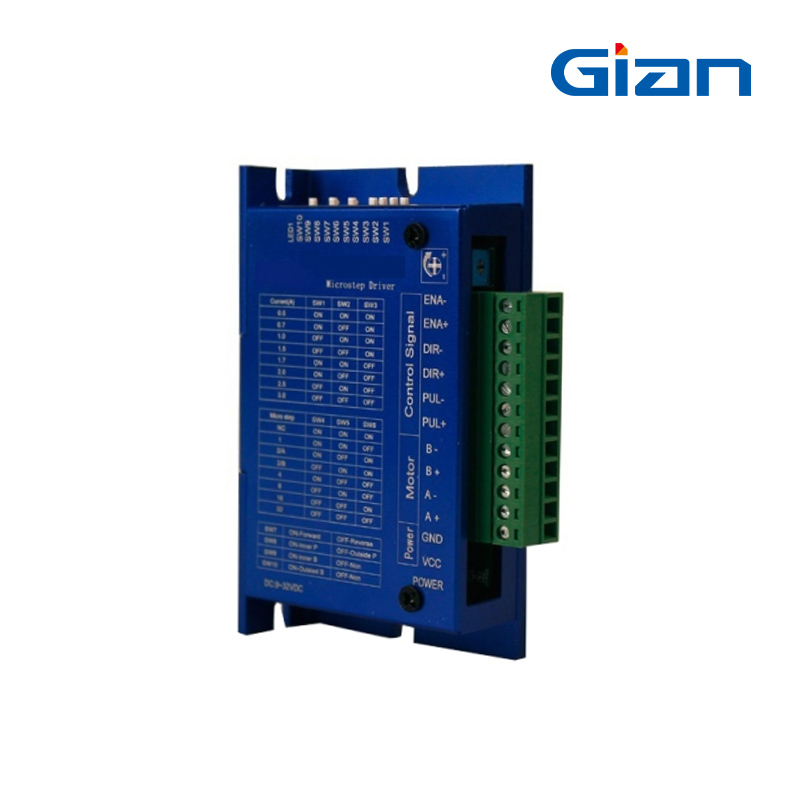

What Is a Motor Driver?

A motor driver is a hardware component that delivers power to the motor according to the control signals it receives. Its main job is to amplify low-power signals and translate them into high-current outputs that drive the motor.

Key Functions:

- Voltage and current amplification

- Direction switching (e.g., H-Bridge for DC motors)

- Switching control for stepper or brushless motors

- Thermal protection or fault monitoring (in advanced drivers)

Hardware-Oriented

Motor drivers are primarily electronic circuit components that bridge logic-level signals and high-power motor phases.

What Is a Motor Controller?

A motor controller is an electronic system (hardware + software) that manages the logic, decision-making, and control algorithms governing motor behavior. It processes user input, sensors, and real-time feedback to produce control signals for the driver.

Key Functions:

- Motion planning (speed, direction, acceleration)

- Feedback processing (via encoders, sensors)

- Closed-loop control (PID, FOC)

- Communication with host systems (e.g., PLC, MCU, PC)

- Safety and diagnostic functions

Software-Oriented

Controllers are more intelligent than drivers. They contain microcontrollers, firmware, or digital logic to dynamically adjust motor performance.

Key Differences Between Motor Drivers and Controllers

| Feature | Motor Driver | Motor Controller |

| Function | Power delivery and switching | Command generation and system logic |

| Complexity | Simple circuitry | Software + hardware system |

| Feedback Integration | Minimal or none | Essential (e.g., encoder, current) |

| Adjustability | Fixed or limited | Highly programmable |

| Position/Speed Control | Not handled | Core functionality |

| Intelligence Level | Low (reactive) | High (adaptive and predictive) |

| Communication Protocols | Rare (unless integrated) | Common (CAN, UART, Modbus, etc.) |

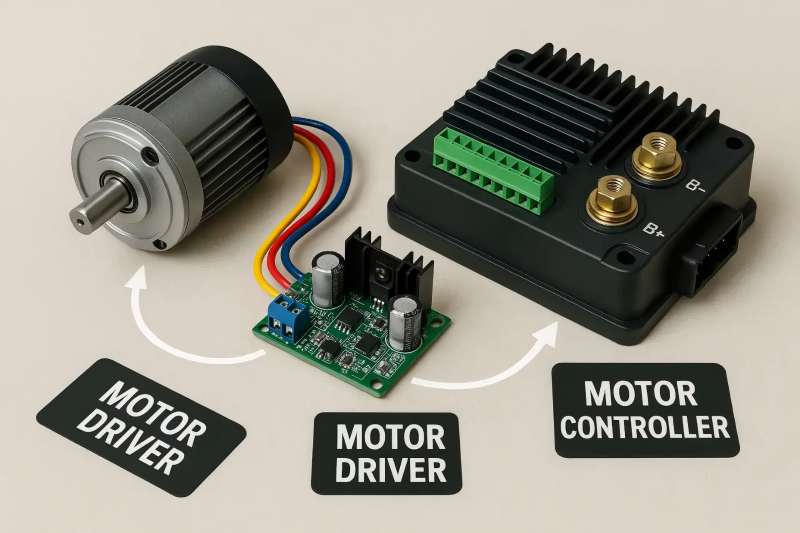

How Motor Drivers and Controllers Work Together

A typical motor control system works in this sequence:

- Input Signal: A host system or user defines motion requirements.

- Motor Controller: Computes control algorithms (e.g., PID, FOC) and generates low-voltage signals.

- Motor Driver: Converts controller signals into high-current waveforms.

- Motor: Executes the command—moves accordingly.

- Feedback Loop: Sensors report back to controller for fine-tuning.

Example:

For a BLDC motor:

- Controller performs Field-Oriented Control (FOC)

- Driver delivers 3-phase pulses

- Encoder reports rotor position

- Controller adjusts the PWM signal accordingly

Types of Motor Controllers

| Controller Type | Description | Typical Motors |

| Open-loop Controllers | No feedback, simple control | Stepper motors |

| Closed-loop Controllers | Uses feedback for dynamic adjustment | Servo, BLDC, PMSM |

| Embedded Controllers | Onboard firmware and microprocessors | Integrated modules |

| External Controllers | Separated logic unit, controls multiple motors | Industrial drives |

Types of Motor Drivers

| Driver Type | Description | Target Motors |

| H-Bridge Drivers | Allows bidirectional current for DC motors | Brushed DC motors |

| Half-Bridge | Drives one direction per phase | BLDC, stepper |

| Full-Bridge | Powers both sides of each motor coil | BLDC, 3-phase motors |

| Gate Drivers | Controls power MOSFETs or IGBTs | High-voltage systems |

| Intelligent Drivers | Combines some control logic (e.g., current limit) | Servo motors |

Motor Driver vs. Motor Controller Comparison

| Aspect | Motor Driver | Motor Controller |

| Function | Converts signals to motor power | Generates and adjusts control signals |

| Core Components | MOSFETs, BJTs, H-Bridge circuits | Microcontrollers, DSPs, firmware |

| Control Level | Low-level, hardware-only | High-level, logic and feedback |

| Signal Input | PWM, logic HIGH/LOW | Serial commands, I/O, sensors |

| Signal Output | Motor coil currents | Driver control signals |

| Communication Capability | Minimal | Full protocol stack (CAN, SPI, RS485) |

| Integration Complexity | Low | Moderate to high |

| Cost | Lower | Higher due to intelligence |

Application-Based Use Cases

Case 1: Small Hobby Robot (Brushed DC Motor)

- Motor Driver: L298N H-Bridge

- Motor Controller: Arduino UNO with PID code

- Role: Arduino sends PWM to L298N → L298N drives motor

Case 2: Industrial Servo System

- Motor: AC Servo Motor with encoder

- Controller: Dedicated servo controller (e.g., Siemens, Delta)

- Driver: High-power inverter with thermal protection

- Role: Controller calculates torque and speed → Driver provides phase current

Case 3: Drone (BLDC Motor)

- Driver: ESC (Electronic Speed Controller, acts as driver)

- Controller: Flight controller (e.g., Pixhawk)

- Integration: Real-time control of propellers with gyro feedback

Manufacturer’s Perspective on Integration and Design

As a motor systems manufacturer, you must consider:

- Custom vs Off-the-Shelf: Whether to design a proprietary driver or use market-available ICs like DRV8880 or TMC2209.

- Integrated Modules: Increasing trend toward integrating driver and controller into one unit for space-saving and reliability.

- Thermal Design: Power drivers require proper heat sinks, PCBs, or MOSFET packages.

- Firmware Development: Custom motor controllers often require months of tuning, algorithm design, and compliance testing.

Example: An integrated servo drive includes both controller and driver in a single enclosure, ideal for AGVs and CNC systems.

Key Considerations for Selecting Drivers and Controllers

| Criteria | Questions to Ask |

| Motor Type | Brushed, BLDC, Stepper, PMSM? |

| Voltage & Current Ratings | What are your motor’s power demands? |

| Control Requirements | Do you need speed, torque, or position control? |

| Feedback Type | Encoder, Hall sensor, sensorless? |

| Communication Protocol | Does it need CANopen, Modbus, or USB interface? |

| Space & Form Factor | Integrated or separated units? |

| Cost Constraints | Is budget or performance more important? |

| Safety & Protection | Are features like OVP, OTP, or stall detection required? |

While motor drivers and motor controllers are sometimes confused, they play very different roles in an electromechanical system. Drivers focus on power delivery, acting as signal amplifiers, while controllers are responsible for intelligent control, signal generation, and feedback processing.

In practice, they work hand-in-hand—one commanding, the other executing. As a manufacturer, choosing the right combination depends on your application’s complexity, performance requirements, cost constraints, and integration needs.

Understanding this distinction helps engineers design more robust, efficient, and cost-effective motion control systems—whether for industrial automation, robotics, EVs, or smart home devices.

Need help selecting or designing the ideal motor control solution for your product? As a trusted manufacturer of motor systems, we offer custom-built motor controllers, integrated driver solutions, and technical consulting tailored to your exact specifications.

Let us know your motor type, application, and performance goals—and we’ll help you build it right.