Motor control systems are central to the functionality of everything from consumer appliances to industrial automation and electric vehicles. In these systems, two core components are often discussed: the motor controller and the motor driver. Although these names are occasionally used interchangeably, they have different functions and differ greatly in terms of cost, complexity, usefulness, and applicability.

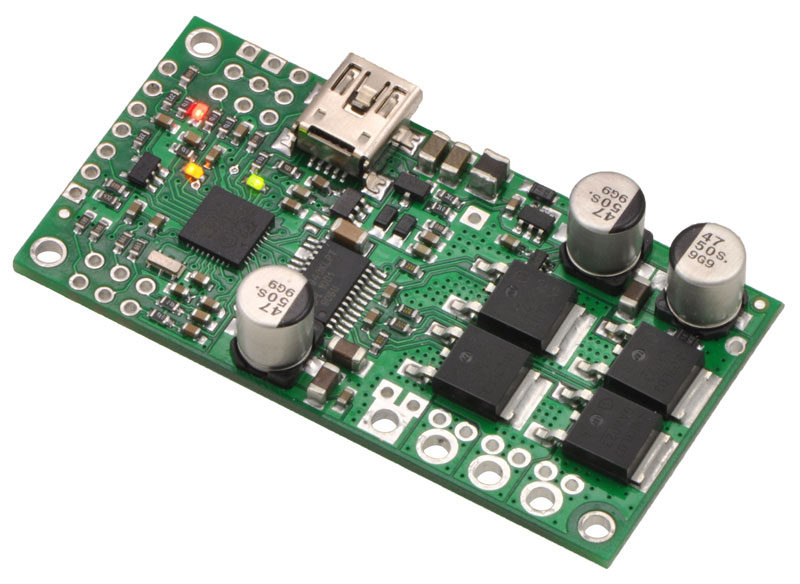

What is a Motor Driver?

A motor and a microcontroller are connected via an electrical device called a motor driver. Its main job is to amplify the microcontroller’s low-power control signals so that the motor may be driven with the required voltage and current. Motor drivers are essential when the control system cannot supply the required power directly to the motor. Arshon Technology

Key Functions of Motor Drivers

- Amplifying PWM signals to control motor voltage

- Handling current demands of the motor

- Enabling forward/reverse control and speed modulation

Common motor drivers include the L298N, DRV8833, and TB6612FNG.

Common Types of Motor Drivers

- H-Bridge Drivers: Used for controlling the direction of DC motors.

- Half-Bridge Drivers: Suitable for applications requiring unidirectional control.

- Full-Bridge Drivers: Allow bidirectional control of motors.Core Electronics

- Three-Phase Drivers: Designed for controlling brushless DC (BLDC) and stepper motors.

Pros | Cons |

|

|

What Is a Motor Controller?

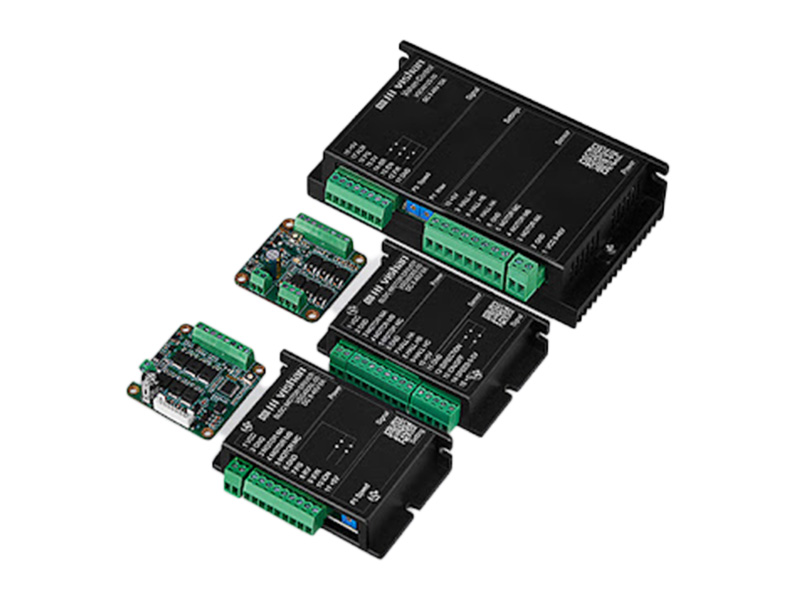

A motor controller, on the other hand, is a more sophisticated device. It not only drives the motor but also manages how the motor performs. Controllers can handle speed regulation, torque control, acceleration profiles, and braking. They often incorporate feedback systems such as encoders or Hall sensors to monitor and adjust motor behavior in real-time.

Advanced controllers may also include:

- Digital signal processors (DSPs)

- Closed-loop control algorithms (PID, FOC)

- Communication interfaces (CAN, UART, Modbus)

- Safety and diagnostic functions

Examples include the VESC (for BLDC motors), Siemens Sinamics drives, and Infineon’s TLE987x series.

Common Types of Motor Controllers

- Open-Loop Motor Controller

- Closed-Loop Motor Controller (Servo Controller)

- Programmable Motor Controller

- Field-Oriented Control (FOC) Motor Controller

Pros | Cons |

|

|

Motor Driver vs. Motor Controller: A Comparative Overview

When to Choose a Motor Driver

Use a motor driver when your application:

- Requires basic control like turning the motor on/off, direction change, or speed via simple PWM.

- Has an external microcontroller or PLC that handles the logic and decision-making.

- Involves open-loop systems where feedback (like from encoders or sensors) is not necessary.

- Needs a cost-effective, lightweight solution with minimal software.

Applies to basic systems like:

- Fans, pumps, and small appliances

- Toy cars or hobby projects

- Entry-level 3D printers

🛠 Example: An H-Bridge driver used with an Arduino to spin a DC motor forward/reverse at variable speeds using PWM.

When to Choose a Motor Controller

Use a motor controller when your application:

- Demands advanced motion control, such as precise speed, torque, or position regulation.

- Needs closed-loop feedback (e.g., encoder, resolver, Hall effect sensors).

- Integrates multiple motors or axes and needs synchronization.

- Requires programmability for profiles like trapezoidal motion or PID tuning.

Used in advanced systems like:

- CNC machines

- Autonomous robots

- Industrial automation

- Electric vehicles

🛠 Example: A Field-Oriented Control (FOC) brushless controller for a robotic arm, managing torque and smooth motion across joints.

Summary Table

| Criteria | Motor Driver | Motor Controller |

| Logic Handling | External MCU handles it | Integrated logic and decision-making |

| Feedback System | Rarely used | Frequently used with sensors/encoders |

| Cost | Lower | Higher |

| Software/Programming | Not needed or minimal | Typically needed |

| Suitable for | Simple tasks | Complex, feedback-driven tasks |

| Examples | DC fans, pumps, hobby motors | Servo systems, CNC, robotics, EVs |

Case Study: BLDC Motor Control

Let’s consider controlling a Brushless DC (BLDC) motor:

- With a Motor Driver: A microcontroller is required in order to produce phase-shifted PWM signals. You would also manually handle commutation based on sensor input.

- With a Motor Controller: A controller like VESC handles all three-phase commutation, torque control, safety limits, and supports various modes (sensorless, FOC, Hall sensor).

Clearly, the motor controller simplifies integration and enhances performance.

Performance Metrics Comparison

| Metric | Motor Driver | Motor Controller |

| Voltage Range | Typically 5V–48V | 5V–600V or more |

| Current Capacity | Up to 10A | Up to 100A+ |

| Precision | Low | High (with feedback) |

| Efficiency | Medium | High (due to algorithms) |

| Setup Time | Fast | Requires configuration |

Development & Debugging Considerations

If you’re developing a product or prototype, the ability to tune your motor control setup is crucial.

- Drivers are best for quick iteration or where minimal behavior customization is needed.

- Controllers offer debugging tools such as serial output, PC-based GUIs, and logs.

For example, with an advanced controller like the VESC Tool, you can log current, RPM, and temperature and adjust settings live.

Popular Components (With Sample Pricing)

| Name | Type | Approx. Price (USD) | Voltage | Current |

| L298N | Driver | $2–$5 | 5–46V | 2A |

| DRV8833 | Driver | $3–$7 | 2.7–10.8V | 1.5A |

| VESC | Controller | $60–$150 | Up to 60V | 50A+ |

| MC33035 | Controller | $10–$30 | Up to 36V | 10A |

Industry Trends

The boundaries between motor controllers and drivers are increasingly blurred. Modern integrated chips like the TI DRV8353 and STSPIN32F0 combine FET drivers, control logic, and protection in one package.

Emerging trends include:

- AI-based predictive control

- Sensorless FOC algorithms

- All-in-one chips with BMS, MCU, and control

Conclusion

The choice between a motor driver and a motor controller ultimately depends on your application’s complexity, control needs, and budget.

- Use a motor driver if you’re building simple systems that don’t need precision

- Use a motor controller when your system requires high reliability, accuracy, and performance.

Understanding the distinction is not just technical—it also impacts how your product scales, performs, and maintains reliability over time. With trends pushing toward smarter, more integrated motor control solutions, knowing when and why to choose one over the other can give your design a clear edge.