In industrial automation, robotics, material handling, and mechanical transmission systems, terms like gear motor and reduced motor are often used interchangeably. This raises the question: Are gear motors the same as reduced motors?

The short answer is no—they are closely related but not exactly the same.

While both gear motors and reduced motors aim to lower speed and increase torque, they differ in structure, integration level, flexibility, installation, and application scenarios. Misunderstanding these differences can result in improper motor selection, higher costs, reduced efficiency, or maintenance challenges.

Basic Definitions

What Is a Reduced Motor?

A reduced motor is a general concept, not a strict product category. It refers to any motor system whose output speed has been reduced using a mechanical reduction mechanism.

A reduced motor usually consists of:

A standard motor (AC, DC, BLDC, or stepper)

An external or separate speed reduction device, such as:

- Gearbox

- Belt and pulley

- Chain and sprocket

- Worm reducer

- Planetary reducer

In simple terms:

If a motor’s speed is reduced before driving the load, it can be called a reduced motor system.

What Is a Gear Motor?

A gear motor is a specific, standardized product in which:

- The motor and gearbox are combined into a single unit.

- The gearbox is directly attached to the motor shaft.

- The output speed and torque are predefined by the internal gear ratio

In other words:

- Every gear motor is a reduced motor, but not every reduced motor is a gear motor.

Core Relationship: Same Goal, Different Concept

Both systems share the same mechanical purpose:

- Reduce rotational speed

- Increase output torque

- Improve load-matching

- Enable controlled motion

However, the difference lies in integration and flexibility.

Key Conceptual Difference

| Aspect | Reduced Motor | Gear Motor |

| Concept | Broad system-level term | Specific motor product |

| Structure | Motor + separate reducer | Motor + built-in gearbox |

| Standardization | Low to medium | High |

| Modularity | High | Low |

Structural Differences Explained

Reduced Motor Structure

A reduced motor system is modular. Engineers can select each component independently:

- Motor type (AC, DC, BLDC, servo)

- Reducer type (planetary, worm, helical)

- Reduction ratio

- Shaft orientation

- Mounting style

Example configurations:

- AC motor + belt reducer

- Servo motor + planetary gearbox

- BLDC motor + harmonic reducer

This flexibility makes reduced motors popular in custom machinery and high-performance systems.

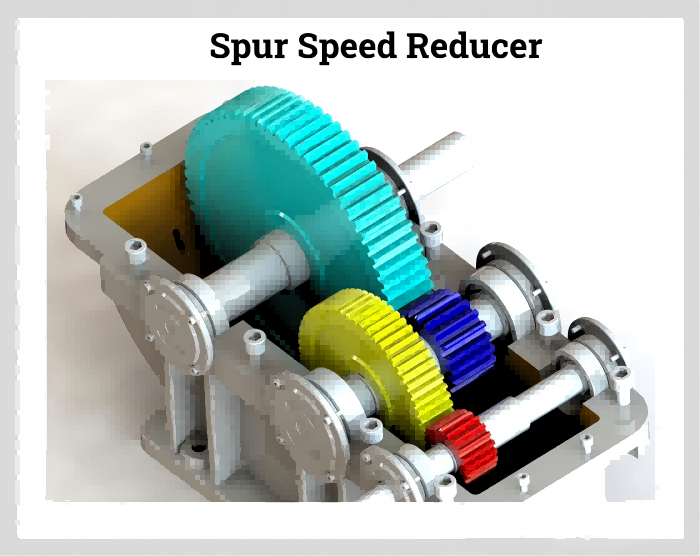

Gear Motor Structure

A gear motor is a pre-engineered, compact unit:

- Fixed motor frame

- Integrated gearbox

- Factory-aligned shaft

- Unified lubrication and sealing

The design prioritizes:

- Ease of installation

- Reliability

- Space efficiency

- Cost control

This makes gear motors ideal for mass-produced equipment.

Functional Comparison Table

| Feature | Reduced Motor | Gear Motor |

| Speed Reduction | Yes | Yes |

| Torque Amplification | Yes | Yes |

| Integrated Design | No (usually) | Yes |

| Custom Gear Ratio | High flexibility | Limited to catalog |

| Maintenance | Component-level | Unit-level |

| Installation | More complex | Simple |

| Footprint | Larger | Compact |

Performance and Efficiency Differences

Efficiency Considerations

Gear motors are optimized as a system, resulting in:

- Lower misalignment losses

- Stable efficiency at rated loads

Reduced motors can achieve:

- Higher efficiency if properly matched

- But efficiency varies based on reducer quality and installation

Torque Density

Gear motors offer high torque density per unit volume

Reduced motors may offer higher absolute torque when using large or specialized reducers

Customization vs Convenience

Reduced Motor: Custom Engineering Advantage

Choose a reduced motor system when:

- Torque requirements vary widely

- Special gear ratios are needed

- High precision or backlash control is critical

- You may need to replace motor or gearbox independently

Common industries:

- Robotics

- CNC machinery

- Automation lines

- Heavy industrial equipment

Gear Motor: Plug-and-Play Advantage

Choose a gear motor when:

- Space is limited

- Cost control matters

- Installation time must be minimal

- Performance requirements are well-defined

Common industries:

- Conveyors

- Packaging machines

- Food processing

- Textile machinery

- Automatic doors

Cost Comparison Table

| Cost Factor | Reduced Motor | Gear Motor |

| Initial Cost | Lower motor, higher system cost | Higher unit cost |

| Engineering Cost | Higher | Lower |

| Installation Cost | Higher | Lower |

| Maintenance Cost | Lower long-term | Higher if failure occurs |

| Replacement Cost | Partial replacement possible | Whole unit replacement |

Maintenance and Serviceability

Reduced Motor Maintenance

| Advantages | Disadvantages |

| Motor and reducer can be serviced separately | More alignment checks |

| Easier upgrades or replacements | More mechanical connections |

| Longer lifecycle in industrial environments |

Gear Motor Maintenance

| Advantages | Disadvantages |

| Fewer external connections | Gearbox failure may require replacing the entire unit |

| Lower routine maintenance | Less flexibility for future upgrades |

Are Gear Motors a Type of Reduced Motor?

Yes—technically and functionally.

From an engineering standpoint:

- A gear motor is a subset of reduced motors

- A reduced motor is a broader system concept

Analogy

Think of it like this:

- Reduced motor = any car with a transmission

- Gear motor = a compact car with an integrated automatic gearbox

Common Misconceptions

❌ “They are the same.”

Not true. One is a broader concept, the other a specific product.

❌ “Gear motors are less powerful.”

Incorrect. Gear motors can deliver extremely high torque relative to size.

❌ “Reduced motors are outdated.”

False. Reduced motor systems dominate high-end automation and robotics.

Selection Guide: Which One Should You Use?

Choose a Gear Motor If:

- You want fast installation

- Space is limited

- Application is standardized

- Budget and simplicity matter

Choose a Reduced Motor System If:

- Custom performance is required

- Torque or speed may change

- Precision and flexibility are critical

- Long-term serviceability matters

Final Conclusion

So, is a gear motor the same as a reduced motor?

No, but they are closely related.

- A gear motor is a fully integrated, standardized reduced motor

- A reduced motor is any motor system using speed reduction

- Gear motors emphasize compactness and convenience

- Reduced motors emphasize flexibility and customization

This distinction helps engineers, buyers, and designers choose the best solution for performance, cost, and reliability.

If you are designing a system where precision, adaptability, or scalability matters, a reduced motor system may be the better choice. If you need simplicity, compact design, and proven reliability, a gear motor is often the optimal solution.