Stepper motors are renowned for their precision and repeatability, making them the go-to choice in automation, 3D printing, CNC machines, and robotics. But without the right stepper motor driver, even the best stepper motor can underperform. As a stepper motor supplier, we’ve encountered countless cases where system failures were traced back to incompatible or underpowered drivers.

What Is a Stepper Motor Driver?

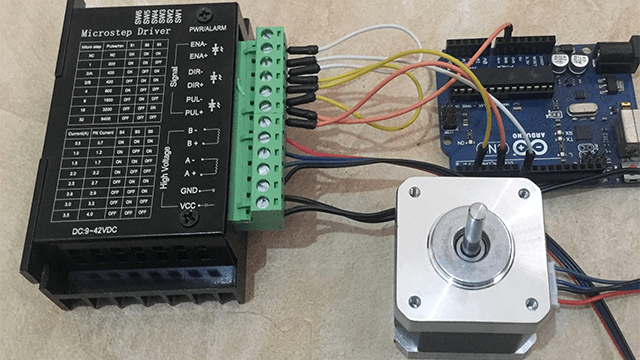

Stepper motor driver supplies current to windings per control signals. It interprets step and direction pulses from a controller or microcontroller (like Arduino, STM32, or PLC) and energizes the coils in the correct sequence to achieve rotation.

Key Functions of a Stepper Driver:

- Interpret control signals (Step and Direction)

- Control the current supplied to the coils

- Enable microstepping for smoother motion

- Manage motor acceleration and deceleration

- Protect against overcurrent, overheating, and undervoltage

Key Parameters to Consider When Choosing a Driver

When selecting a stepper motor driver, you should first match it to your motor’s electrical and mechanical characteristics. Here are the essential factors:

Motor Type (Unipolar vs Bipolar)

| Motor Type | Description | Driver Requirement |

| Unipolar | Has center-tapped coils. Easier to drive but lower torque. | Compatible with unipolar driver (5 or 6 wires) |

| Bipolar | No center tap, requires H-bridge. Offers more torque. | Needs bipolar driver (4 wires) |

Bipolar motors are more common due to their better torque-to-size ratio.

Voltage and Current Ratings

Match the voltage and current ratings of the motor and driver:

- Current (A/phase): The driver must handle the motor’s rated current per phase. Always choose a driver with 10–20% higher current capability for headroom.

- Voltage (V): Higher voltage provides better high-speed performance but must stay within driver limits.

| Example Stepper Motor | Rated Current | Recommended Driver Current |

| NEMA 17 (42HS40) | 1.5 A | 1.7 – 2.0 A |

| NEMA 23 (57BYGH76) | 2.8 A | 3.0 – 3.5 A |

Microstepping Support

Microstepping improves motion smoothness and resolution. Common microstep levels:

| Microstepping Mode | Steps per Revolution (1.8° motor) |

| Full step | 200 steps |

| Half step | 400 steps |

| 1/4 step | 800 steps |

| 1/16 step | 3200 steps |

| 1/32 step | 6400 steps |

More microsteps = smoother movement but requires more precise signals and may reduce torque slightly.

Control Interface

Choose a driver that matches your control system:

| Control Type | Interface | Typical Use |

| Step/Dir | TTL input | Arduino, PLCs, CNC |

| UART/I2C | Serial bus | Advanced microcontroller control |

| USB/CAN | Host control | Robotics, Industrial control |

For most applications, Step/Dir control is the most straightforward and widely supported.

Key Driver Selection Criteria

Current Rating Compatibility

The driver’s current rating should closely match the motor’s phase current rating. Many modern drivers offer current adjustment via DIP switches or software. Undersupplying current results in low torque, while oversupplying can overheat the motor.

- Best Practice: Choose a driver that supports at least 10% more current than the motor’s rated current, but never exceed the motor’s max current rating.

Voltage Rating

Higher voltage increases motor speed and dynamic torque but also increases power dissipation. Always ensure the driver supports the required voltage range of the motor.

- Tip: If your stepper motor is rated at 3V and 2A, a driver operating at 24V can greatly improve performance through faster coil energization.

Microstepping Capability

Microstepping divides steps for smoother motion and finer position resolution. Select a driver based on the resolution required by your application.

| Microstepping Mode | Steps Per Revolution (for 1.8° Motor) |

| Full Step | 200 |

| Half Step | 400 |

| 1/4 Step | 800 |

| 1/8 Step | 1600 |

| 1/16 Step | 3200 |

- Application Tip: Use higher microstepping for precision applications like 3D printers or camera positioning.

Control Interface Compatibility

Ensure the driver accepts the control signal format provided by your motion controller:

- Step/Direction (most common for CNC and 3D printing)

- Pulse Width Modulation (PWM)

- Serial (UART/I²C/SPI)

- Analog control

- CANopen or EtherCAT for industrial applications

Driver Type (Chopper vs. L/R Drive)

| Type | Description |

| L/R Drivers | Simple, use resistors to limit current, less efficient |

| Chopper Drivers | Use high-frequency switching to regulate current dynamically, more efficient |

Chopper drives are now the industry standard due to their performance and efficiency.

Choosing the Driver Type

Here are the most common driver technologies:

L/R (Linear Resistance) Drivers

- Simple, low-cost

- Best for low-speed, low-performance applications

- Limited efficiency

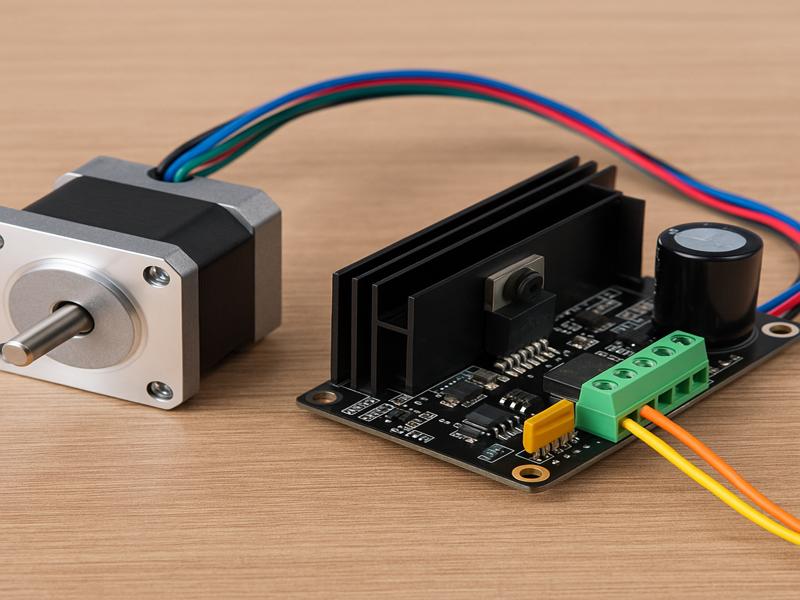

Chopper (PWM Current Control) Drivers

- Use pulse-width modulation to control coil current

- More efficient

- Allow for microstepping and dynamic current control

- Examples: A4988, DRV8825, TB6600

Closed-Loop Stepper Drivers

- Include an encoder for feedback

- Prevent missed steps

- Offer servo-like performance

- Higher cost, used in demanding applications

| Driver Type | Cost | Feedback | Suitable For |

| L/R Driver | Low | No | Basic DIY or educational |

| PWM Driver | Medium | No | 3D printers, CNC, general automation |

| Closed-loop | High | Yes | Robotics, precision motion, heavy loads |

Stepper Motor Driver Selection Table

Here’s a quick reference chart of common stepper motors and suitable drivers:

| Motor Model | Size | Voltage | Current | Suitable Driver Model | Microstepping | Notes |

| 42HS40 NEMA 17 | 17 | 12V | 1.5A | A4988, DRV8825 | 1/16 | Good for 3D printers |

| 57BYGH76 NEMA 23 | 23 | 24–48V | 2.8A | TB6600, DM542 | 1/32 | CNC router, laser engraver |

| 86BYG250 NEMA 34 | 34 | 48V | 6.0A | DM860, Leadshine CL86T | Closed-loop | Heavy-duty applications |

Additional Features to Look For

When choosing a driver, these features can enhance performance and reliability:

Overcurrent and Overtemperature Protection

Shields motor and driver from damage caused by overload or overheating.

Adjustable Current Limiting

Allows fine-tuning to match motor specs and prevent excessive heating.

Idle Current Reduction

Reduces current when motor is idle, lowering heat and power consumption.

Built-in Heat Sink or Fan

Essential for higher-current drivers to maintain temperature stability.

Matching Driver with Power Supply

Ensure power supply meets voltage and current needs for both.

| Motor Driver | Recommended Supply Voltage | Notes |

| A4988 | 8–35V | Use 12V or 24V for better performance |

| DRV8825 | 8.2–45V | Good for mid-range motors |

| TB6600 | 9–42V | Use 24V or higher for torque at speed |

| DM542 | 18–50V | Industrial-grade, excellent for NEMA 23 |

- Rule of thumb: Total current = 1.5x motor rated current (for margin)

Application Examples

Example 1: 3D Printer (NEMA 17 + A4988)

- Low torque, high precision

- Low cost, space-constrained

- Driver: A4988 or DRV8825

- Power: 12–24V @ 2A

Example 2: CNC Router (NEMA 23 + TB6600)

- Medium torque, rapid motion

- Driver: TB6600 or DM542

- Power: 24–48V @ 4A

Example 3: Conveyor Belt System (NEMA 34 + Closed-Loop Driver)

- High torque and feedback required

- Driver: Leadshine CL86T

- Power: 48V @ 6–8A

Common Mistakes to Avoid

- Underrated Driver Current: Can lead to skipped steps or stalled motion.

- Wrong Control Interface: Causes communication failure with your microcontroller or PLC.

- Poor Cooling: Leads to overheating and driver shutdown.

- Noisy Motion: Caused by lack of microstepping or poor PWM frequency.

- Overdriving Voltage: Damages driver or motor insulation.

Choosing the right driver is not just about matching specs. You must understand your application demands, motor characteristics, and performance goals. The right driver ensures smooth, efficient, and long-lasting stepper operation.

Whether you’re building a hobbyist 3D printer or an industrial CNC system, use this guide to compare driver options based on current, voltage, control method, microstepping, and protection features.

Still unsure? As a professional stepper motor and driver supplier, we offer technical support and help match the right driver for your application needs. Contact us anytime!