Selecting the right gear motor ensures reliable, efficient operation. Whether you’re automating conveyor belts, driving packaging lines, or powering robotics, proper gear motor sizing ensures that your system performs as expected without overspending on capacity or risking premature failure.

Why Gear Motor Sizing Matters

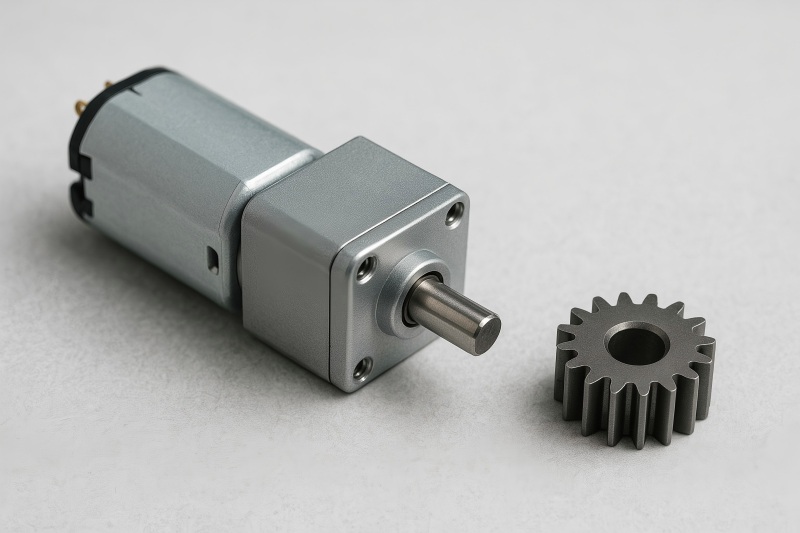

Gear motors pair an electric motor with a gearbox, boosting torque and reducing speed. Incorrect sizing risks inefficiency, damage, or failure:

- Undersized motors overheat, stall, or wear out prematurely.

- Oversized motors waste energy, cost more, and take up unnecessary space.

- Incorrect sizing can lead to inaccurate motion control, mechanical stress, or production downtime.

For manufacturers, proper sizing isn’t just a technical task—it’s also a business decision that affects productivity, energy consumption, maintenance costs, and equipment lifespan.

Understanding Gear Motor Basics

Before diving into sizing, let’s review the three core parameters:

Torque

Torque is the rotational force a motor provides to drive a load. In gear motors, torque is amplified through gear reduction, allowing a smaller motor to move heavier loads at lower speeds.

Speed

Speed refers to the output rotational speed after gear reduction. Gearboxes reduce motor speed to match application requirements, such as the linear speed of a conveyor or the rotational speed of a drum.

Power

Power represents the rate of doing work, or how much mechanical energy the motor can deliver. It links torque and speed together, typically expressed in watts or horsepower.

Understanding the balance between these three parameters helps you define the operating window your gear motor must meet.

Step-by-Step Gear Motor Sizing Process

Step 1: Define the Application Requirements

Start by outlining the exact mechanical task the gear motor will perform:

- Type of motion: Linear, rotational, stop-start, or continuous motion types

- Load characteristics: Steady, fluctuating, or sudden impact loads

- Desired speed: Conveyor belt speed, rotational speed of a shaft, or travel time for a mechanism

- Duty cycle: How often the motor will start/stop and how long it will operate per cycle

- Operating environment: Temperature, humidity, cleanliness, or explosive atmospheres

Clearly defining these parameters ensures the selected motor can handle real-world operating conditions, not just ideal lab scenarios.

Step 2: Determine the Load Torque

Torque depends on the load type and mechanical setup:

- Conveyor belts: Torque depends on belt tension, friction, and weight of transported goods.

- Lifting mechanisms: Torque is tied to the weight and radius of pulleys or drums.

- Rotating machinery: Torque comes from resistance in gears, rollers, or attached equipment.

For example, in conveyor applications, you’d consider startup torque (overcoming static friction) and running torque (maintaining steady motion). This ensures the motor can start smoothly under load.

Step 3: Calculate Required Output Speed

Next, identify the speed the driven equipment must run. Usually shown in RPM or linear speed (m/min).Examples:

- Conveyor belt speed: 20 m/min

- Drum rotation: 30 RPM

- Packaging line indexing: 1 cycle every 2 seconds

Once you know the required output speed, you can work backward to determine motor speed and gear ratio. Most electric motors operate at fixed speeds (e.g., 1,400 RPM for 4-pole AC motors), so the gearbox is used to reduce this to the desired output speed.

Step 4: Select a Suitable Gear Ratio

The gear ratio determines how motor speed is reduced and torque is increased:

- High gear ratios → Lower output speed, higher torque

- Low gear ratios → Higher output speed, lower torque

Choosing the right ratio ensures the motor operates near its optimal speed range, which improves efficiency and longevity.

For example, to achieve an output of 35 RPM from a motor running at 1,400 RPM, you’d need a gear ratio of 40:1.

Step 5: Check Motor Power Requirements

With the torque and speed defined, calculate the required motor power. Although formulas exist, manufacturers often provide selection charts or software tools where you input torque and speed to find the recommended motor power rating.

Consider the following:

- Continuous operation vs intermittent

- Efficiency losses in gearboxes (typically 85–95%)

- Safety factors to accommodate unexpected load variations

It’s good practice to add a safety margin, typically between 10–30%, to avoid running the motor at its maximum capacity continuously.

Step 6: Consider Duty Cycle and Thermal Limits

Gear motors generate heat when operating. Frequent starts, stops, or long cycles make the motor’s thermal capacity critical.

- S1 (Continuous duty): Motor runs continuously at a constant load.

- S2 (Short-time duty): Runs briefly, then cools before reuse.

- S3 (Intermittent duty): Motor cycles between operation and rest.

Ensure the selected motor can dissipate heat according to your duty cycle. Oversized motors may run cooler but waste energy, while undersized ones may overheat quickly.

Step 7: Verify Gearbox Strength and Service Factor

The gearbox must withstand both torque and shock loads. Manufacturers specify:

- Rated torque: Continuous torque the gearbox can transmit

- Peak torque: Short-term torque during startup or overload

- Service factor: Multiplier to account for load variations (e.g., light, medium, heavy duty)

For example, a packaging line with smooth motion might use a service factor of 1.0–1.2, while a rock crusher or agitator might need 1.5 or higher.

Step 8: Account for Mounting and Integration

Finally, consider how the gear motor will fit mechanically:

- Shaft orientation: Inline, right-angle, or parallel

- Mounting: Foot, flange, or shaft-mounted

- Space constraints: Gear motors can be bulky, especially at high gear ratios

- Coupling methods: Direct coupling, belt drives, or chain drives

Integration considerations can affect heat dissipation, alignment, and ease of maintenance, all of which influence motor performance and lifetime.

Common Gear Motor Sizing Mistakes

Even experienced engineers can make sizing errors. Here are some typical pitfalls to avoid:

Mistake 1: Ignoring Starting Torque

Starting torque is often higher than running torque. If the motor can’t deliver enough torque during startup, it may stall or trip protective devices.

Mistake 2: Overlooking Peak Load Events

Applications such as indexing or intermittent drives can have short bursts of high torque. Failing to account for these can damage gears and shafts.

Mistake 3: Neglecting Efficiency Losses

Gearbox and mechanical losses reduce available power. Selecting a motor based only on output power without considering efficiency leads to undersized systems.

Mistake 4: Oversizing “Just to Be Safe”

While adding safety margins is wise, excessive oversizing wastes energy, increases cost, and can create control issues, especially in variable speed applications.

Mistake 5: Forgetting Thermal Ratings

Running a motor continuously at near-maximum capacity accelerates insulation aging and shortens service life. Always check thermal limits for your duty cycle.

Practical Example: Conveyor Application

Let’s apply the sizing steps to a horizontal conveyor transporting boxes:

- Conveyor length: 10 m

- Belt speed: 20 m/min

- Box weight: 15 kg each, with 10 boxes on the conveyor

- Drive roller diameter: 100 mm

- Operating mode: Continuous

Step 1 – Output speed:

Roller circumference ≈ 0.314 m. At 20 m/min, roller must turn ≈ 64 RPM.

Step 2 – Torque estimation:

Based on belt friction and load weight, required output torque might be 40 Nm (running) and 60 Nm (startup).

Step 3 – Gear ratio:

Motor speed 1400 RPM → 1400 / 64 ≈ 22:1 gear ratio.

Step 4 – Power check:

From manufacturer charts, 40 Nm at 64 RPM roughly equals 270 W output power. Considering gearbox efficiency and startup torque, a 0.55 kW (550 W) gear motor would be appropriate.

Step 5 – Duty cycle:

Continuous operation, so select S1-rated motor.

Step 6 – Mounting:

Flange-mount, inline gear motor fits conveyor frame.

This example demonstrates how to match speed, torque, and power without complicated formulas, using practical application data and standard gear motor selection charts.

Special Considerations for Different Motor Types

AC Gear Motors

- Best for constant-speed applications.

- Simple, cost-effective, and durable.

- Speed controlled by gear ratio or external inverter.

DC Gear Motors

- Offer variable speed control and easy torque adjustment.

- Widely used in mobile and low-voltage systems.

- Need careful attention to voltage and current.

BLDC (Brushless DC) Gear Motors

- High efficiency, compact, and low maintenance.

- Perfect for precise speed control and durability.

- Paired with planetary or helical gearboxes for high torque density.

Stepper Gear Motors

- Excellent for positioning applications.

- Lower power than BLDC but precise at low speeds.

- Often used with worm or spur gearboxes for compact designs.

Choosing the right motor type influences control strategy, size, efficiency, and integration options.

Using Manufacturer Tools and Selection Charts

Most reputable gear motor manufacturers provide selection software, online calculators, or printed catalogs that simplify the sizing process. You typically enter:

- Required speed

- Torque or load data

- Mounting style

- Duty cycle and environment

The software then suggests motor and gearbox combinations that meet your requirements. Some advanced tools even check service factors, thermal limits, and peak loads automatically.

Using these resources ensures you pick the most cost-effective and technically suitable solution without oversizing.

Safety Margins and Reliability

When finalizing your gear motor selection, always build in reasonable safety margins:

- Torque margin: 10–30% above calculated requirement

- Thermal margin: Ensure motor operates below its max temperature rise

- Mechanical margin: Gearbox service factor ≥ 1.25 for general industrial use

These margins protect against unexpected conditions, such as increased friction, heavier loads, or slight misalignments, without resorting to excessive oversizing.

Maintenance and Lifecycle Considerations

Sizing doesn’t end at installation. A well-sized gear motor also enables predictable maintenance cycles and long service life:

- Proper sizing avoids excessive wear on bearings, gears, and seals.

- Correct thermal loading preserves motor insulation.

- Balanced speed and torque improve energy efficiency over years of operation.

For manufacturers, these factors reduce downtime, spare parts inventory, and total cost of ownership.

Sizing a gear motor correctly is both a technical process and a practical decision. By clearly defining your application, calculating required torque and speed, selecting appropriate gear ratios, and considering duty cycles and service factors, you can choose a gear motor that delivers reliable, efficient performance for years.

Whether your application involves conveyors, mixers, packaging machines, or robotics, the principles remain the same: match the motor’s power, torque, and speed to the actual needs of the task—not just rough estimates.