Outrunner BLDC motors are renowned for their high torque-to-weight ratio, efficiency, and compact form factor, making them the go-to choice in drones, RC aircraft, electric skateboards, robotics, and industrial tools. However, overheating remains one of the most frequent problems faced by operators.

Overheating can shorten the lifespan of a motor, degrade magnets, damage windings, and in severe cases cause total failure. As a manufacturer, we have encountered these problems stemming from diverse mechanical, electrical, and operational factors. In this guide, we’ll break down:

- Why outrunners overheat – the physics and mechanisms

- Common root causes – electrical, mechanical, environmental

- Diagnostic steps – how to pinpoint the problem

- Permanent fixes – engineering and operational solutions

- Preventive maintenance tips

- Case studies with data

Heat in Outrunners

Outrunners generate heat primarily from electrical and magnetic losses, along with mechanical friction. These include:

- Copper losses (I²R losses): Energy loss in the windings increases with the square of the current due to their electrical resistance.

- Iron losses: Magnetic hysteresis and eddy current losses within the stator laminations.

- Magnet losses: Eddy currents in permanent magnets, especially at high RPM.

- Mechanical losses: Bearing friction and air drag (windage).

- ESC inefficiency: Poor commutation timing or low efficiency generating heat that conducts into the motor.

When these heat sources exceed the motor’s ability to dissipate thermal energy via conduction, convection, and radiation, temperature rises—leading to overheating.

Root Causes of Overheating in Outrunners

We group them into electrical, mechanical, and environmental categories.

Electrical Causes

Overcurrent draw

- Motor draws more current than its continuous rating.

- Common in over-propped drones or under-rated ESCs.

Excessive load torque

- Heavy payloads or mechanical resistance cause the ESC to push more current.

Poor ESC timing

- Incorrect commutation timing leads to incomplete power transfer and more copper losses.

Low-efficiency ESC operation

- Using PWM-based controllers without proper tuning increases phase current ripple.

FOC misconfiguration

- In field-oriented control, incorrect parameters can increase Iq current unnecessarily.

Mechanical Causes

Improper propeller sizing

- Larger or higher-pitch propellers create excessive load.

Bearing wear

- Increases mechanical friction and heat generation.

Rotor imbalance

- Causes vibration and uneven bearing loading.

Obstructed ventilation

- Outrunners rely on rotor rotation to circulate air; obstructions hinder cooling.

Environmental Causes

High ambient temperature

- Less temperature gradient between motor and air reduces cooling rate.

Altitude changes

- Lower air density at high altitudes reduces cooling efficiency.

Enclosed installations

- Motors mounted in closed frames without airflow overheat faster.

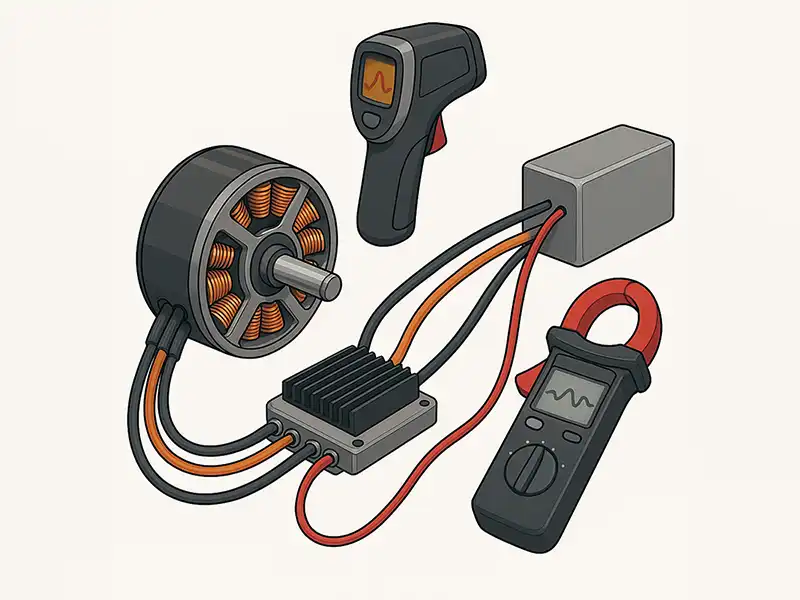

Diagnostic Steps for Overheating

Step 1: Measure Current Draw

Use a wattmeter or ESC telemetry to compare actual current draw vs. motor’s continuous current rating.

Overcurrent at expected throttle points to load or ESC issues.

Step 2: Check Motor Temperature

Use an infrared thermometer or thermocouples.

Safe range: Most outrunners handle 80–100 °C winding temp before insulation damage.

If magnets exceed 80 °C (Neodymium N35–N52 grades), risk of demagnetization.

Step 3: Inspect Mechanical Components

Spin rotor by hand; resistance indicates bearing or friction issues.

Listen for grinding or irregular sound.

Step 4: Review ESC Configuration

Check timing advance settings (e.g., 5°–15° typical for BLDCs).

For FOC, verify motor constants (Kv, pole pairs, resistance, inductance) are correct.

Step 5: Evaluate Propeller and Load

Compare propeller size to manufacturer’s recommended load chart.

Test with a smaller propeller to see if heat drops.

Step 6: Check Airflow

Observe whether the rotor is unobstructed and air can circulate.

Root Causes and Fixes Table

| Root Cause | Symptom | Fix |

| Over-prop / excessive load | High current at moderate throttle | Reduce prop size or pitch |

| ESC timing too high/low | Motor runs hot even at low load | Adjust timing in ESC firmware |

| Bearing wear | Grinding noise, higher no-load current | Replace bearings |

| Rotor imbalance | Vibration, uneven heating | Balance rotor with weights |

| Poor ventilation | Temp rise in still air | Improve airflow, add ducts |

| High ambient temp | Overheats faster outdoors | Limit throttle or improve cooling |

| Incorrect FOC parameters | Higher phase current than expected | Calibrate motor constants |

Permanent Fixes

Load Optimization

- Use manufacturer’s thrust/current charts to match prop size and battery voltage.

- Avoid over-propping, especially on hot days.

ESC Optimization

- Upgrade to an FOC-capable ESC for smoother, more efficient operation.

- Tune PWM frequency and timing advance for the specific motor.

Thermal Management

- Add aluminum heatsinks to motor base.

- Direct cooling airflow over stator.

- Use vented rotors or fan-blade designs to improve self-cooling.

Mechanical Maintenance

- Replace bearings periodically with high-quality, low-friction types.

- Balance props and rotors to minimize vibration.

Electrical Safeguards

- Use ESC with thermal and overcurrent protection.

- Add in-line current monitoring to detect anomalies early.

Preventive Maintenance Tips

Regular Current Monitoring

Keep logs via telemetry to spot trends in rising current draw.

Prop Inspection

Replace cracked or bent props to maintain balance.

Bearing Lubrication

Use light oil for shielded bearings every 50–100 operating hours.

ESC Firmware Updates

Manufacturers often release timing or thermal control improvements.

Test Under Load

After changes, run motor at target throttle for 2–3 minutes and measure temperature rise.

Case Study Data

Case 1: Drone Racing Outrunner Overheating

- Motor: 2207, 2500 KV

- Prop: 5×4.5

- Battery: 4S LiPo (16.8 V full)

- Symptom: 90 °C after 1 min full throttle

- Diagnosis: Current draw 38 A vs. 30 A continuous rating

- Fix: Switched to 5×4 prop → Current drop to 29 A → Max temp 74 °C

Case 2: E-Skate Hub Motor

- Motor: 6374, 170 KV

- Load: Heavy rider, steep hills

- Symptom: ESC thermal shutdown after 10 min climb

- Diagnosis: High continuous torque demand

- Fix: Reduced gearing ratio for higher RPM at lower torque, added ESC heatsink → No shutdown

Example Safe Operating Temperature Table

| Motor Class | Continuous Current Rating | Max Safe Winding Temp | Max Magnet Temp (N52) |

| 2205–2306 | 20–25 A | 100 °C | 80 °C |

| 2808–3110 | 30–40 A | 110 °C | 80 °C |

| 5010–6310 | 40–70 A | 120 °C | 80 °C |

| 6374+ | 70–120 A | 130 °C | 80 °C |

Overheating in outrunner BLDC motors is not inevitable—it’s preventable with correct sizing, tuning, and maintenance. By understanding the interplay of electrical load, mechanical condition, and cooling efficiency, you can diagnose problems early and apply fixes that extend motor life.

As a manufacturer, we recommend oversizing components for demanding applications, choosing ESCs with proper control algorithms, and ensuring cooling airflow is never compromised. In performance systems like drones, RC racing, and e-bikes, these steps not only prevent failures but also maximize efficiency and runtime.