Brushless DC motors (BLDC motors) have revolutionized electric motion systems across industries—from drones and robotics to EVs and industrial automation—due to their efficiency, longevity, and reliability. However, one persistent question often arises: Can a BLDC motor run without a controller?

The short answer is no, not effectively or safely. But to fully understand why, we must explore how BLDC motors work, the role of the controller, what happens without one, and whether any workarounds exist for specific use cases.

What’s a Brushless DC Motor?

A Brushless DC motor is a synchronous motor that runs on direct current (DC) and operates without brushes or a mechanical commutator. Instead of using physical contacts, it relies on electronic communication to sequentially energize the stator windings according to the rotor’s position.

Key Components of a BLDC Motor:

| Component | Description |

| Stator | Generates rotating magnetic field using internal copper windings. |

| Rotor | Typically constructed using high-strength permanent magnetic materials. |

| Hall Sensors | Detect the rotor’s position (in sensored BLDC motors) |

The Role of a BLDC Motor Controller

A BLDC controller is the brain of the system, enabling the motor to spin properly by:

- Interpreting the rotor position (via sensors or sensorless algorithms)

- Generating accurate timing signals (commutation)

- Switching power to the correct coils using transistors or MOSFETs

- Adjusting speed, torque, direction, and braking functions

Without this controller, a BLDC motor does not receive the correct phase timing, resulting in either complete inactivity or erratic, unsafe behavior.

Why BLDC Motors Not Run Without a Controller?

No Built-In Commutation

Unlike brushed DC motors that use a mechanical commutator and brushes to switch current between windings, BLDC motors rely on external electronics to perform this task. Without the precise phase switching provided by a controller, the stator coils are never energized in the right sequence.

- Conclusion: No built-in mechanism means no movement without external commutation.

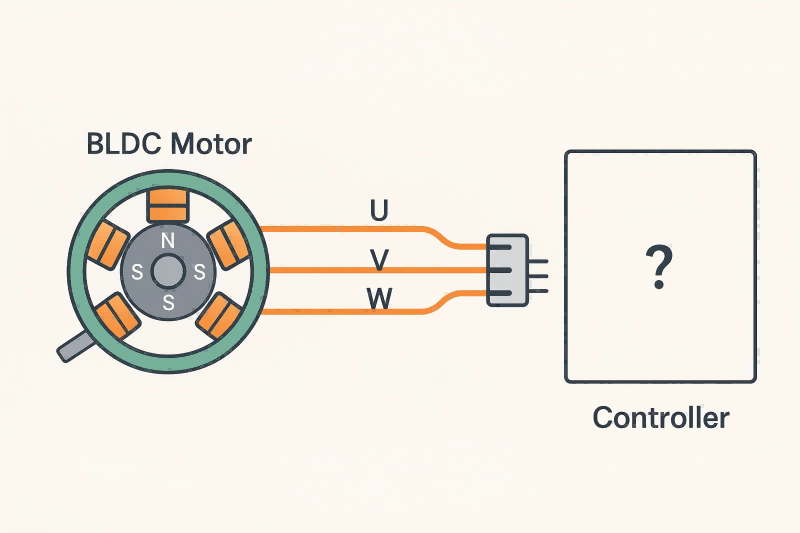

Complex Timing Requirements

BLDC motors typically have three phases (U, V, W). Energizing the correct coil at the correct time is essential. The controller must:

- Monitor the rotor’s position in real time

- Adjust PWM signals based on load and speed

- Switch high currents with microsecond-level precision

Manually replicating this process is nearly impossible without a purpose-built driver/controller.

What Happens If You Try?

Here’s what you might encounter if you attempt to run a BLDC motor without a controller:

| Scenario | Result |

| Connecting DC directly to coils | The motor won’t rotate or may jerk briefly; overheating is likely |

| Using random AC signals | The motor vibrates, stalls, or emits noise—no useful motion |

| Applying mechanical commutation | Not possible due to construction; unlike brushed motors |

| Replacing controller with relays | Inaccurate, unstable, and inefficient (rare DIY experiments only) |

Warning: Attempting to power a BLDC motor this way can permanently damage the windings, overheat the rotor, and void warranties.

Are There Any Exceptions or Workarounds?

While running a BLDC motor without a dedicated controller is generally not viable, there are some rare, limited-use workarounds:

Manual Commutation with Arduino (Educational Purposes Only)

In controlled lab environments, microcontrollers like Arduino can simulate commutation by sending phase signals manually, but this requires:

- Knowing the motor’s electrical characteristics

- Using high-power MOSFETs

- Writing complex timing code

Drawback: It’s not scalable, lacks protection features, and is unsafe for commercial use.

Using Sensorless Drivers with Built-In Control Logic

Some ICs combine basic control with driver functions, such as:

| Component | Function |

| DRV10983 | Sensorless BLDC motor driver with built-in control loop |

| LV8907 | Advanced sensorless driver for automotive motors |

| MC33035 (obsolete) | Early-generation motor controller IC |

These chips blur the line between “driver” and “controller” and can technically run BLDC motors on their own—but they are still controllers in the architectural sense.

ESCs (Electronic Speed Controllers)

Widely used in drones and RC vehicles, ESCs are compact modules that integrate a controller and driver in one. They often accept PWM, analog, or serial inputs and are essentially a controller for BLDC motors.

Reminder: Even if a module looks like a simple plug-and-play unit, it has a controller built inside—it’s not running the motor “without” one.

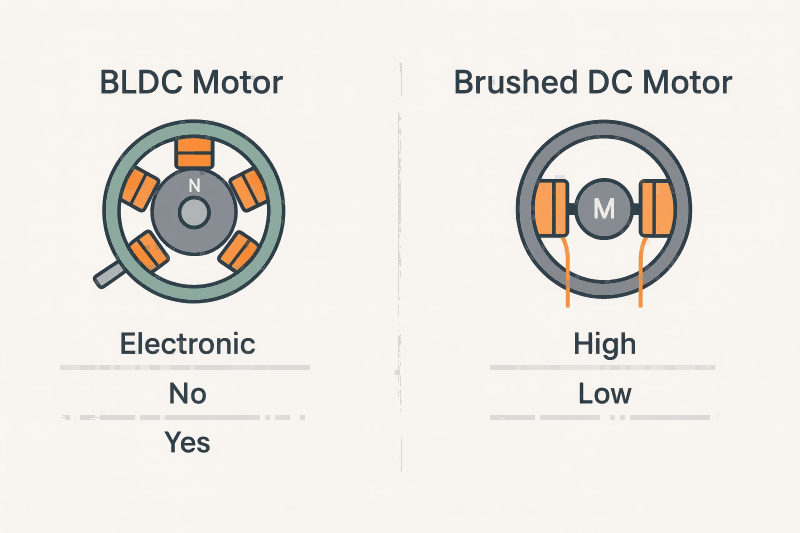

BLDC vs. Brushed Motor Comparison

To understand the necessity of a controller, compare BLDC with brushed DC motors:

| Feature | Brushed Motor | Brushless DC Motor |

| Commutation Type | Mechanical (brush & commutator) | Electronic (external controller) |

| Can Run Without Control? | Yes (direct DC supply) | No |

| Efficiency | Moderate | High |

| Maintenance | Requires frequent servicing | Low maintenance |

| Lifetime | Shorter (brush wear) | Longer |

Bottom line: Only brushed motors can run off direct power due to their self-commutation system.

The Importance of Motor Controllers in Real Applications

Let’s examine real-world systems where controllers are mandatory:

| Application | Why Controller Is Essential |

| Drones | Provides high-speed commutation, throttle control, and braking |

| EVs | Controls torque, regenerative braking, speed modulation |

| Industrial Fans | Ensures soft start, fault protection, efficient power use |

| CNC Machines | Maintains positional accuracy, handles load feedback |

| Medical Devices | Delivers precise speed control, safety features, error handling |

No professional-grade system would operate a BLDC motor without a smart controller.

Safety and Efficiency Concerns Without a Controller

Trying to operate a BLDC motor without a controller leads to:

- Overheating: Stalled or misfiring coils build up excessive heat

- Unstable Operation: Erratic speed, vibration, and low torque

- Electrical Damage: Uncontrolled current flow may destroy windings

- No Feedback or Protection: No current limit, temperature check, or short-circuit detection

What Proper BLDC Controller Provides

| Feature | Function |

| Commutation Algorithm | Manages phase switching |

| Speed Control | Regulates motor speed via PWM or voltage control |

| Current Limiting | Prevents burnout under load |

| Position Feedback (optional) | Enables closed-loop control using encoders or Hall sensors |

| Braking & Reversing | Implements regenerative or electronic braking |

| Communication Interface | Accepts input via PWM, UART, CAN, SPI, or analog signals |

GIAN’s Recommendation

As a BLDC motor manufacturer, we strongly recommend never attempting to operate a BLDC motor without a dedicated controller. Instead, use one of the following:

- Integrated Controller-Driver Modules for compact applications

- Smart ESCs for drones and e-mobility

- Advanced Industrial Controllers for servo-grade performance

- Custom Firmware Controllers (e.g., FOC-based STM32) for robotics and automation

These ensure maximum efficiency, durability, and safety.

So, can you run a brushless DC motor without a controller? Technically, no. Practically, absolutely not.

While it’s theoretically possible to create crude workarounds in a lab, real-world operation without a controller will result in inefficient, unsafe, and often destructive outcomes. The controller is not optional—it is essential for harnessing the power and precision that makes BLDC motors so widely adopted.

As a trusted manufacturer of high-performance BLDC motors and integrated motion systems, we offer not just motors, but also controller and driver solutions tailored to your application—whether in robotics, EVs, or smart appliances.

Looking for guidance on choosing the ideal BLDC motor and controller combination? Contact us for expert consultation and OEM-ready solutions.