Gearboxes are the quiet workhorses behind countless machines—from small conveyors and packaging equipment to cranes, wind turbines, and automotive drivetrains. Choosing the right gearbox type is not just a mechanical decision; it determines efficiency, noise, cost, service life, and even safety.

Here’s a practical guide to the five most common gearbox types—spur, helical, bevel, worm, and planetary—and how to decide when each one makes the most sense.

What a Gearbox Actually Does

A gearbox is a power-transmission device that:

- Changes speed up or down

- Multiplies torque

- Changes the direction of rotation or power flow

In most industrial and automation settings, electric motors run fast but don’t provide enough torque at the shaft for direct use. The gearbox sits between the motor and the driven machine, adjusting speed/torque to match the application and sometimes redirecting motion (for example, 90° power transfer in bevel or worm gearboxes).

Different gearbox types achieve this in different ways, with trade-offs in efficiency, compactness, cost, noise, and load capacity.

Comparing the Main Gearbox Types

Here’s a quick high-level comparison before we dive into each type:

| Gearbox Type | Typical Gear Orientation | Main Advantages | Common Use Cases |

| Spur | Parallel shafts, straight teeth | Simple, low cost, high efficiency | Simple machinery, low/medium speed drives |

| Helical | Parallel or crossed, angled teeth | Quieter, higher load capacity, smoother motion | Industrial drives, conveyors, compressors |

| Bevel | Intersecting shafts (often 90°) | Changes direction, compact right-angle layout | Right-angle drives, gearboxes, differentials |

| Worm | 90° shafts, worm & worm wheel | High reduction ratio, self-locking possible | Lifts, hoists, gates, positioning systems |

| Planetary | Coaxial (input & output aligned) | Very high torque density, compact, precise | Robotics, servo drives, heavy-duty drives |

Spur Gear Gearboxes

A spur gearbox uses straight-tooth gears parallel to the rotation axis. Shafts are typically parallel, and gear meshing is straightforward. Because of the simple geometry, these are often the first choice for basic speed reduction and torque increase.

Key Characteristics

- Tooth form: Straight teeth, parallel to the shaft

- Shaft arrangement: Parallel only

- Load capacity: Good for moderate loads

- Efficiency: Very high (often 95–98% per stage in well-designed units)

- Noise: Can be noisy at high speeds due to impact

- Manufacturing complexity: Lowest of the five types, which keeps costs down

Advantages of Spur Gearboxes

- Low cost: Easy to manufacture and assemble.

- High efficiency: Minimal sliding between teeth means relatively low friction.

- Easy to design and maintain: Well understood, widely standardized.

- Low–medium torque use: When noise doesn’t matter.

Limitations of Spur Gearboxes

- Noise and vibration: Sudden tooth engagement generates more noise, especially at high speeds.

- Not ideal for very high-speed applications: Dynamic loads and noise increase significantly.

- Limited torque density: Larger units may be needed compared to helical or planetary designs.

When to Use a Spur Gearbox

Choose spur gearboxes when:

- You need a simple, economical gearbox.

- Noise level is not a critical concern—for example, in enclosed machinery or industrial environments.

- Application speeds are moderate, and torque levels are not extremely high.

You want easy service and replacement with common parts (small conveyors, simple mixers, agricultural machinery, low-end gear motors).

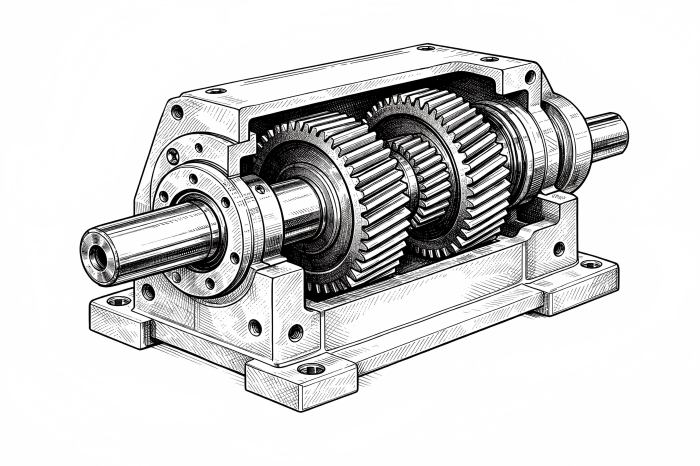

Helical Gear Gearboxes

A helical gearbox uses helical gears—teeth cut at an angle to the shaft, forming a helix. As gears mesh, contact starts gradually and spreads across the tooth, which reduces impact and noise.

- Helical gears can work with:

- Parallel shafts (most common)

- Crossed shafts (for certain special arrangements)

Key Characteristics

- Tooth form: Angled teeth, gradual engagement

- Shaft arrangement: Parallel or crossed

- Load capacity: Higher than spur gears of similar size due to more tooth contact area

- Efficiency: High, though slightly lower than spur due to sliding friction

- Noise: Quieter and smoother than spur gears.

- Axial load: Generates axial thrust that must be absorbed by bearings

Advantages of Helical Gearboxes

- Smooth and quiet operation: Gradual tooth engagement reduces shock and noise.

- Higher load capacity: More teeth in contact at once.

- Better suited for high speeds: Preferred in many industrial drives and automation applications.

- Versatile configurations: Inline, parallel-shaft, or even right-angle (via crossed helical or helical-bevel combinations).

Limitations of Helical Gearboxes

- Axial thrust: Requires robust bearings and housing to handle axial forces.

- Lower efficiency vs spur: More sliding contact.

- Higher manufacturing cost: More complex gear cutting and finishing.

When to Use a Helical Gearbox

Pick helical gearboxes when:

- You need quieter, smoother operation than spur gears can provide.

- The drive runs at higher speed and/or in continuous duty.

- Medium to high torque is required with reasonable compactness.

Applications include conveyors, compressors, blowers, process equipment, and many industrial gear motors and reducers.

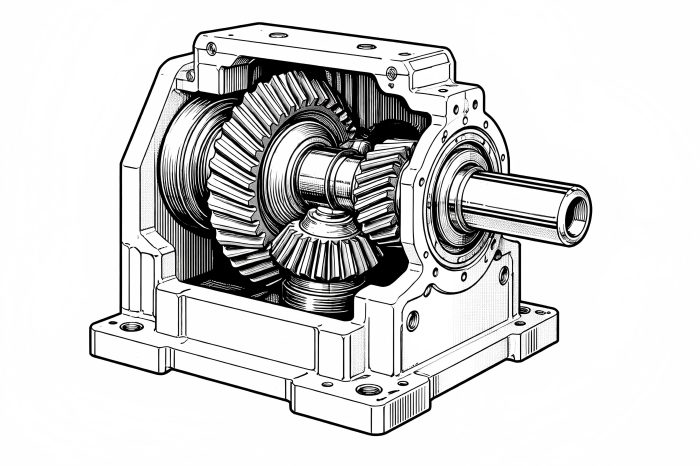

Bevel Gear Gearboxes

Bevel gearboxes use bevel gears, which have conical pitch surfaces and are designed to transmit power between intersecting shafts—commonly at 90°. They can be straight bevel, spiral bevel, or hypoid (offset) designs.

Key Characteristics

- Tooth form: Straight, spiral, or hypoid

- Shaft arrangement: Intersecting (usually at 90°), sometimes offset (hypoid)

- Function: Changes direction of power, often within a compact right-angle housing

- Load capacity: Good to high, especially for spiral bevel and hypoid designs

- Noise: Straight bevel can be noisy; spiral bevel and hypoid are quieter

Advantages of Bevel Gearboxes

- Right-angle power transmission: Ideal when you must turn motion 90° in a compact form.

- High efficiency (especially spiral bevel): Better than worm gearboxes for right-angle drives.

- High torque capability: Can handle substantial loads in appropriately sized units.

Limitations of Bevel Gearboxes

- Complex machining and assembly: Precise alignment and gear cutting required.

- Higher cost than spur or simple helical gearboxes.

- Sensitive to misalignment: Incorrect setup leads to noise and premature wear.

When to Use a Bevel Gearbox

Use a bevel gearbox when:

- You need to change direction of rotation by 90° and maintain good efficiency.

- Compact right-angle layout is critical (e.g., when space is limited).

You need medium to high torque with relatively high efficiency—such as in mechanical drives, industrial reducers, agricultural machinery, or vehicle differentials (often hypoid/spiral bevel).

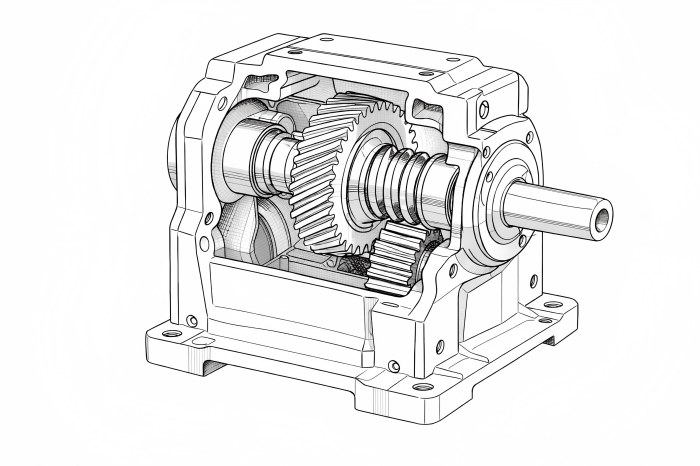

Worm Gear Gearboxes

A worm gearbox uses a screw-like worm and wheel at 90°. The worm drives the worm wheel, typically delivering high reduction ratios in one stage.

Key Characteristics

- Shaft arrangement: Right-angle, non-intersecting shafts

- Reduction ratios: Very high (e.g., 20:1, 60:1, even 100:1 in one stage)

- Directionality: Often non-reversible (self-locking in some configurations)

- Efficiency: Lower than helical or bevel due to high sliding friction

Advantages of Worm Gearboxes

- High reduction in a compact package: Ideal when you need large speed reduction quickly.

- Self-locking capability: In some designs, the output cannot back-drive the input, so the system can hold a load without brakes.

- Smooth, quiet operation at low speed: Good for controlled motion.

- Simple layout for right-angle drive: Compact 90° power transfer.

Limitations of Worm Gearboxes

- Lower efficiency: Sliding friction between worm and wheel generates heat and energy loss.

- Heat management needed: High reduction and high load can lead to overheating.

- Wear and lubrication sensitivity: Poor lubrication or overload accelerates wear of the worm wheel.

When to Use a Worm Gearbox

Worm gearboxes are ideal when:

- You need high reduction ratios but have limited space.

- Self-locking is helpful for safety (hoists, lifts, swing gates, positioning tables).

- The system runs intermittently or at lower duty so efficiency loss and heat are manageable.

Examples: small lifting devices, hoists, gate actuators, conveyors with holding requirements, adjustable platforms.

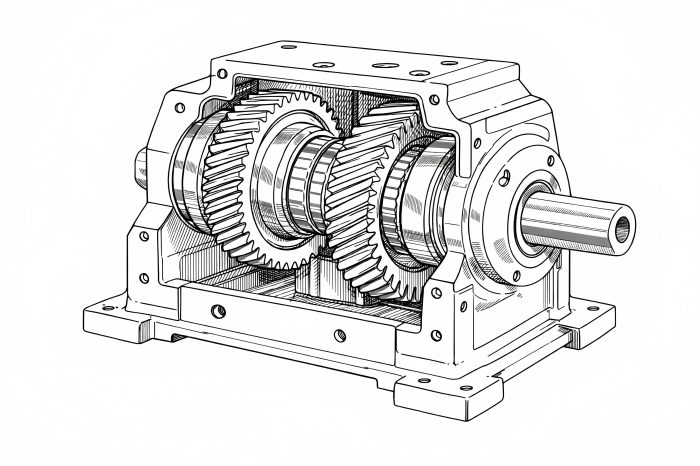

Planetary Gear Gearboxes

A planetary (epicyclic) gearbox consists of:

- Sun gear: Central gear

- Planet gears: Multiple gears rotating around a central sun gear

- Planet carrier: Structure supporting and positioning planet gears

- Ring gear: Outer gear featuring internal teeth

By locking different elements and using multiple stages, planetary gearboxes produce very high torque in a compact, coaxial arrangement.

Key Characteristics

- Coaxial input and output: Very compact along the axis.

- High torque density: Load shared across multiple planets.

- High reduction capacity per stage: Often 3:1 to 10:1 per stage, with multi-stage assemblies reaching much higher ratios.

- Efficiency: High, especially for high-quality precision units.

- Backlash: Can be very low in precision designs for servo/robotic use.

Advantages of Planetary Gearboxes

- Extremely compact for given torque: Great power-to-weight and torque-to-volume ratio.

- Excellent load distribution: Multiple gear meshes share the load evenly.

- Versatile configurations: Many ratios and options via modular stages.

Limitations of Planetary Gearboxes

- More complex design and manufacturing: More components and tighter tolerances.

- Higher cost: Especially in precision servo-grade planetary gearboxes.

- More sensitive to contamination and poor lubrication: Many contact points must be properly lubricated.

When to Use a Planetary Gearbox

Choose a planetary gearbox when:

- You need high torque in a small volume (robot joints, wheel drives, compact industrial drives).

- Servo or stepper motors require accurate positioning with low backlash.

- Limited space requires high reduction ratios and high stiffness.

Typical applications: robotics, CNC axes, electric vehicle drives, winches, aerospace and high-performance industrial gear motors.

Side-by-Side: Which Gearbox Fits Which Requirement?

To quickly narrow down choices, it helps to judge each gearbox type by key decision factors.

Selection Comparison Table:

| Requirement / Factor | Spur Gearbox | Helical Gearbox | Bevel Gearbox | Worm Gearbox | Planetary Gearbox |

| Direction change needed (90°) | ✖ Not suitable | ◑ Only with add-ons | ✔ Yes, primary use | ✔ Yes | ✖ Normally coaxial |

| Highest efficiency priority | ✔ Very high | ✔ High | ✔ High (spiral bevel) | ✖ Lower (friction) | ✔ Very high |

| Lowest cost priority | ✔ Best choice | ◑ Moderate | ✖ Higher | ◑ Moderate | ✖ Highest |

| High reduction ratio in 1 stage | ✖ Limited | ◑ Moderate | ◑ Moderate | ✔ Excellent | ◑ Good (multi-stage better) |

| Very compact, high torque | ◑ Decent | ✔ Good | ◑ Good | ◑ Good at low speed | ✔ Excellent |

| Very quiet, smooth operation | ✖ Noisy at speed | ✔ Good | ✔ Good (spiral/hypoid) | ✔ Quiet at low speed | ✔ Excellent |

| Self-locking needed | ✖ No | ✖ No | ✖ No | ✔ Often available | ◑ With special design only |

| Precision / low backlash | ◑ Possible | ✔ Good with fine gears | ✔ Good with spiral bevel | ✖ Not ideal | ✔ Best option |

Practical Application Scenarios

Here’s how to choose in typical real-world situations.

Conveyor Systems in a Factory

Need: Continuous duty, medium speed, moderate noise, reliable and efficient.

Best fits:

- Helical gearboxes (inline or parallel shaft) for main conveyor drives.

- Spur gearboxes for simpler, low-speed, low-cost auxiliary drives.

Lifts, Hoists, and Positioning Tables

Need: High reduction, sometimes self-locking to hold loads, compact right-angle layout.

Best fits:

- Worm gearboxes for high ratio plus self-locking (if overall efficiency is acceptable).

- Worm + helical combinations where you want better efficiency but still high reduction.

Robotics and Servo Motion Systems

Need: Compact, high torque, low backlash, precise positioning.

Best fits:

- Planetary gearboxes as the primary choice.

- Sometimes precision helical gearboxes for larger axes.

Automotive and Vehicle Drivetrains

Need: Direction changes, efficiency, compactness, and high torque.

Best fits:

- Bevel / hypoid gearboxes in differentials and final drives.

- Planetary gear sets used in automatics and EV drivetrains

Simple Industrial Machinery (Mixers, Agitators, Packagers)

Need: Reliable torque, cost-effective, moderate speed.

Best fits:

- Spur gearboxes where noise is not a major issue.

- Helical gearboxes if better for smoothness, quietness, or longer life is needed.

Other Key Factors in Gearbox Selection

Beyond type, always consider:

Load and Duty Cycle

- Continuous vs intermittent: Worm boxes in heavy continuous duty can overheat; high-efficiency helical or planetary units may be better.

- Shock loads: Choose gearboxes with robust gears and couplings (often helical or planetary) if frequent shocks occur.

Speed and Ratio Requirements

If you need very high reductions (over 20–30:1 per stage), worm or multi-stage planetary/helical combinations often make sense.

For moderate ratios (3:1 to 10:1), spur and helical gearboxes are usually sufficient.

Space and Layout Constraints

- Right-angle layouts: Bevel or worm.

- Coaxial, ultra-compact: Planetary.

- Simple parallel-shaft layout: Spur or helical.

Efficiency and Energy Cost

- In systems running long hours every day, efficiency losses multiply into real energy costs.

- Favor helical, bevel, or planetary over worm if power consumption matters.

- Consider worm gearboxes primarily where self-locking or cost/value trade-offs justify the losses.

Accuracy and Backlash

- For positioning systems (servo drives, robotics, indexing tables), backlash is critical.

- Precision planetary and precision helical gearboxes are preferred.

- Worm gearboxes generally have more backlash and are not ideal for precise positioning.