Choosing between a spur gearbox and a helical gearbox looks simple on paper: both reduce speed, multiply torque, and transmit power. In practice, “performs better” depends on what you care about—efficiency, noise, load capacity, durability, footprint, cost, maintenance, and how forgiving the gearbox is in real-world conditions.

What is a Spur Gearbox?

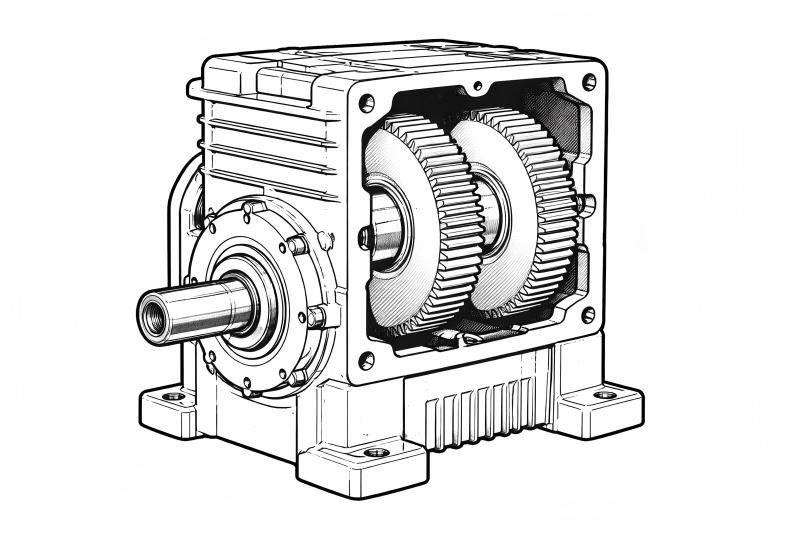

A spur gearbox uses spur gears, which have straight teeth cut parallel to the gear axis. When two spur gears mesh, the tooth contact happens mostly all at once across the face width, and the force is transmitted primarily as tangential force (the useful torque component) plus a radial force pushing the gears apart.

Key characteristics

- Simple geometry and manufacturing

- No axial thrust from the gear mesh (in ideal alignment)

- Typically lower cost for comparable sizes

- Can be very efficient, especially at moderate speeds

- May generate higher noise at elevated speeds from sudden tooth contact.

Spur gearboxes are commonly found in simpler drives where noise is not critical, costs must be controlled, and loads are moderate.

What is a Helical Gearbox?

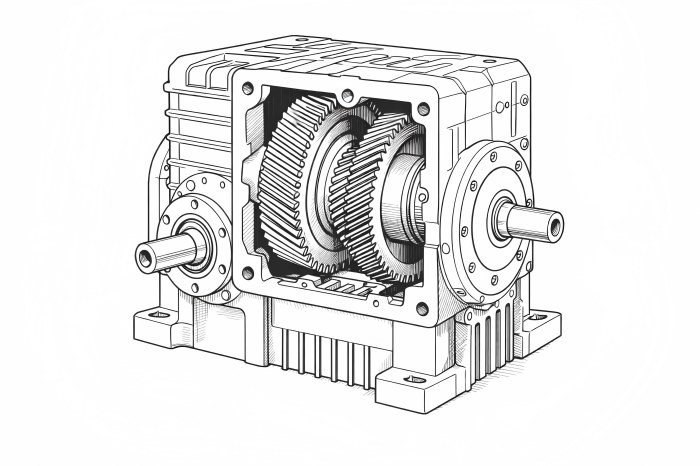

A helical gearbox features angled teeth that engage gradually along the gear face, creating smooth, continuous contact and quieter power transmission during operation. This gradual engagement increases the contact ratio (more teeth share load at once) and reduces vibration.

Key characteristics

- Smoother, quieter operation

- Higher load capacity for the same gear size (often)

- Produces axial thrust, which requires thrust bearings and proper housing stiffness

- Slightly more sliding action than spur gears, which can increase heat and reduce peak efficiency

- Typically higher cost and more complex bearing/support requirements

Helical gearboxes are popular in industrial drives where smoothness, noise control, and durability under load matter.

The Core Mechanical Difference: Tooth Engagement

A good way to understand performance is to compare how the teeth meet:

- Spur gears: Engagement is comparatively sudden. Impact-like tooth entry and exit can excite vibration, especially at higher pitch-line velocities and with manufacturing tolerances.

- Helical gears: Engagement is gradual. Load is shared across multiple teeth, reducing peak tooth loads and smoothing torque ripple.

That “smoothness” is why helical gearboxes are often described as more “premium.” But premium isn’t automatically better—because you pay for it in axial thrust, bearings, and cost.

Performance Comparison Table

Below is a high-level comparison. “Better” here means “typically more favorable,” assuming similar quality level, materials, and lubrication.

| Category | Spur Gearbox | Helical Gearbox |

| Noise & vibration | Louder at high speed; more gear whine | Quieter; smoother torque transmission |

| Load capacity (same size) | Moderate | Higher (often) due to load sharing |

| Efficiency | Very high at moderate speeds/loads | Slightly lower due to sliding + thrust losses |

| Axial thrust | Minimal/none (ideal) | Significant; needs thrust bearings |

| Cost | Lower | Higher |

| Manufacturing complexity | Lower | Higher |

| Bearing requirements | Simpler | More demanding (thrust + stiffness) |

| Suitability for high speed | Okay, but noise rises | Strong choice (quiet, smooth) |

| Suitability for shock loads | Can be good, but tooth impact matters | Often better load distribution, but bearings see thrust |

Efficiency: Which One Is More Efficient?

Both can be highly efficient—especially when well-designed and properly lubricated. But in many real-world cases:

- Spur gears often achieve slightly higher mesh efficiency because their tooth contact involves less sliding relative to helical gears.

- Helical gears introduce more sliding due to angled teeth, which can increase frictional losses and heat.

- Helical gearboxes also add thrust-bearing losses, because axial forces must be supported.

Practical takeaway on efficiency

- If your priority is maximum efficiency, moderate speed, and you don’t need ultra-quiet operation, spur gearboxes can be excellent.

- If you prioritize smoothness and quiet, the small efficiency penalty of helical can be worth it.

In many industrial settings, the efficiency difference is not huge, but it becomes more noticeable at:

- Higher speeds

- Higher loads

- Higher oil temperatures

- Lower-quality lubrication regimes

- Poor alignment or excessive bearing preload

Noise, Vibration, and “Feel” of the Drive

Noise is where helical gearboxes usually win clearly.

Why spur gears can be noisy

Spur gear teeth engage more abruptly. Any slight mismatch—micro-geometry errors, pitch variation, shaft deflection, or housing compliance—turns that engagement into vibration. At higher speeds, gear mesh frequency rises and the noise becomes more obvious.

Why are helical gears quieter

Helical teeth enter mesh gradually, distributing load over time. Higher contact ratio means:

- Lower dynamic load spikes

- Less gear whine

- Reduced torque ripple

Practical takeaway on noise

- For HVAC fans, conveyors near operators, robotics, packaging lines, helical is often preferred.

- For simple machinery, intermittent duty, outdoor equipment, spur can be perfectly acceptable.

Torque Capacity and Durability Under Load

Helical gearboxes often outperform spur gearboxes for torque density in the same envelope, mainly because:

- More tooth contact is engaged at any moment

- Load sharing reduces peak stress on any single tooth pair

- Smoother engagement reduces dynamic overloads

However, it’s not as simple as “helical always handles more torque.” Two important realities:

Bearing and housing limits can dominate.

A helical gearbox’s tooth mesh may tolerate high load, but the resulting axial thrust can overload bearings or distort the housing, leading to misalignment and premature wear.

Spur gears can be extremely strong too.

A properly sized spur gearbox with robust shafts, quality heat treatment, and good lubrication can be very durable.

Practical takeaway on load

- If you need high continuous torque or high shock tolerance with smooth transmission, helical is often the better baseline.

- If loads are moderate and you can size up slightly, spur can be rugged and cost-effective.

Axial Thrust: The “Hidden Cost” of Helical

This is the biggest technical tradeoff.

- Helical gears create axial thrust on the shaft that must be properly supported.

- Requires support from thrust, tapered roller, or angular contact bearings

- Increases bearing heat and wear if not designed properly

- Requires a stiffer housing to control shaft deflection

- Can increase sensitivity to misalignment and assembly errors

What this means in practice

A helical gearbox often needs:

- Better bearings

- Better oil management (heat and film strength)

- Stronger housing and shaft support

- More careful assembly and alignment

So while helical gears are smoother, the overall gearbox is more complex and usually more expensive—both to buy and sometimes to maintain.

Backlash, Positioning, and Control

Backlash is the free movement between meshing teeth. It matters when:

- You reverse direction frequently

- You do positioning (indexing tables, actuators)

- You care about stiffness in servo systems

Both spur and helical gearboxes have backlash, but:

- Helical gears can feel “tighter” due to smoother engagement and potentially higher overlap, but they still require proper backlash setting.

- Spur gears are common in simple reductions, and backlash can be noticeable if tolerance is wide.

If you need precision:

- Look for precision-grade gearing, preloaded designs, or planetary gearboxes (often used with servos).

- Don’t assume helical automatically equals low backlash—quality and design class matter more.

Thermal Behavior and Lubrication

Helical gears can generate more heat because:

- More sliding occurs in the mesh

- Thrust bearings add friction

- Higher load density is often used (smaller gearbox for same torque), raising thermal stress

Spur gears can run cooler under the same operating condition, but:

- If spur gears are noisy or vibrating, dynamic loads can also create heat and wear.

Lubrication notes

- Spur gearbox: often forgiving with splash lubrication at moderate speeds.

- Helical gearbox: may require better oil selection (viscosity, EP additives) and possibly better cooling for high-duty cycles.

Cost, Availability, and Lead Time

Spur gearboxes generally win on:

- Lower manufacturing cost

- Simpler bearing system

- Easier machining and inspection

- Wider availability for basic, commodity reducers

Helical gearboxes cost more due to:

- More complex gear cutting and finishing

- Higher bearing costs and tighter assembly requirements

- Stronger housings to manage thrust loads and deflection

Spur is often preferred when budget is limited and noise isn’t a concern.

If downtime is expensive and comfort/quiet matters, helical can justify itself quickly.

Application Guidance: Which Should You Choose?

Here’s a practical decision map.

Choose a spur gearbox when:

- Cost sensitivity is high

- Speeds are moderate and noise is acceptable

- Loads are moderate and duty cycle is not extreme

- You want a simpler, robust, easy-to-service reducer

- The environment is rough and you prefer “less to go wrong”

Common examples:

- Small conveyors

- Agitators at moderate speed

- Simple machinery drives

- Farm equipment or rugged utility drives (depending on design)

Choose a helical gearbox when:

- Low noise and smooth running matter

- High speed input is common

- High continuous torque or long duty cycles are required

- You want better load sharing and reduced vibration

- The gearbox is near operators or in noise-sensitive facilities

Common examples:

- Packaging and bottling lines

- Fans, blowers, compressors (where noise/vibration matters)

- Industrial conveyors with long run times

- Mixers or process equipment with steady high loads

“Which One Performs Better?” A Scoring Table

If you want a fast answer: helical gearboxes often “perform better” in smoothness and heavy-duty operation, while spur gearboxes often “perform better” in simplicity and cost-efficiency.

| Priority | Better Typical Choice | Why |

| Quiet operation | Helical | Gradual tooth engagement, less vibration |

| High-speed smoothness | Helical | Lower dynamic loads, better NVH |

| Highest mechanical simplicity | Spur | No thrust loads; simpler bearings |

| Lowest cost | Spur | Easier manufacturing and assembly |

| Best for heavy continuous duty | Helical | Load sharing, reduced peak tooth stress |

| Best for easiest maintenance | Spur | Fewer thrust-related issues |

| Best efficiency (often) | Spur | Less sliding + fewer thrust losses |

Common Misconceptions

“Helical is always more efficient.”

Not necessarily. Helical can be very efficient, but spur often has a slight edge at comparable conditions.

“Spur gearboxes can’t handle heavy loads.”

They can, if sized and built properly. The limitation is often noise, dynamic load, and how the system tolerates shock and vibration.

“Helical gearboxes are always quieter.”

Usually yes, but poor bearing setup, bad alignment, or low-quality tooth finishing can still create noise.

“Gear type isn’t the only factor to consider.”

Quality matters as much as type:

- Gear material and heat treatment

- Tooth finishing (grinding/honing)

- Shaft stiffness and bearing selection

- Housing rigidity

- Lubrication quality and sealing

- Assembly alignment and preload control

A high-quality spur gearbox can outperform a poorly built helical gearbox in real life.

Final Recommendation

If your definition of “better performance” is quiet, smooth, high-load, high-speed industrial duty, the answer is usually helical gearbox—because the tooth engagement and load sharing produce a more stable, refined drive.

If your definition of “better performance” is high efficiency, simplicity, ruggedness, and cost effectiveness in moderate-speed, moderate-load applications, a spur gearbox often performs better overall.

Rule of thumb:

- Helical = better “industrial performance feel” (quiet + load handling).

- Spur = better “value performance” (simple + efficient + affordable).