In industrial motion control systems, selecting the right drive solution is critical for performance, efficiency, reliability, and cost control. Two commonly confused components in this decision process are gearboxes and geared motors. Although closely related and often used together, they are not identical.

Understanding their differences is essential for engineers, procurement teams, and system designers who want to optimize mechanical performance while avoiding over-engineering or unnecessary expenses.

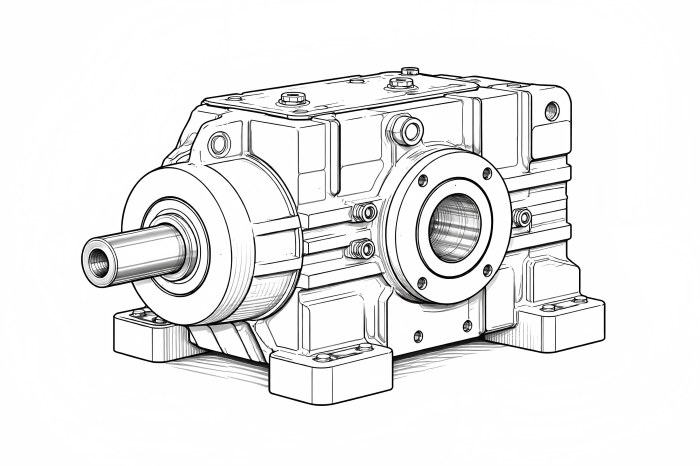

What Is a Gearbox?

A gearbox is a mechanical device that adjusts speed, torque, and direction without generating power. Instead, it relies on an external motor—such as an AC motor, DC motor, servo motor, or engine—to supply input power.

Core Functions of a Gearbox

- Speed increase or reduction

- Torque multiplication

- Change in rotation direction

- Load matching between motor and driven equipment

Basic Structure of a Gearbox

A typical gearbox consists of:

- Gear sets (spur, helical, bevel, worm, or planetary)

- Input shaft

- Output shaft

- Bearings

- Housing

- Lubrication system (oil or grease)

- Seals and cooling features (for heavy-duty gearboxes)

Common Gearbox Types

- Spur gear gearbox

- Helical gearbox

- Bevel gearbox

- Worm gearbox

- Planetary gearbox

- Cycloidal gearbox

Each type is optimized for specific load conditions, space constraints, noise requirements, and efficiency levels.

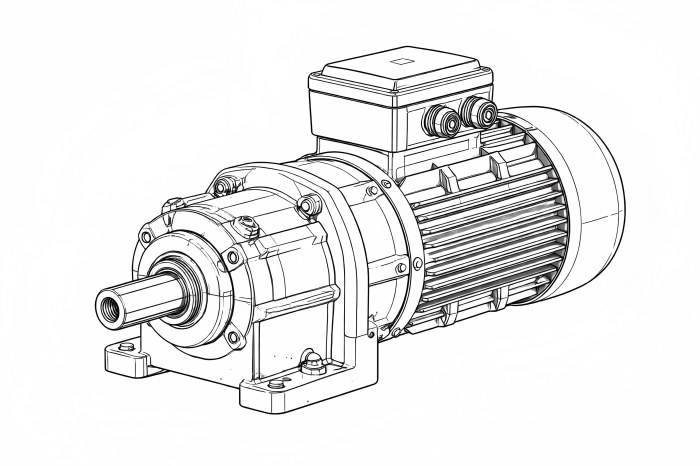

What Is a Geared Motor?

A geared motor integrates an electric motor and gearbox into one compact, efficient drive unit. The motor and gearbox are engineered to work together as one matched system.

In a geared motor:

- The motor provides rotational power

- The gearbox modifies speed and torque

- Both components share a common housing or flange interface

Types of Motors Used in Geared Motors

- AC induction motors

- DC brushed motors

- Brushless DC (BLDC) motors

- Servo motors

- Stepper motors

Common Geared Motor Configurations

- AC geared motor

- DC geared motor

- BLDC geared motor

- Servo geared motor

- Worm geared motor

- Planetary geared motor

Because the motor and gearbox are factory-matched, geared motors are widely used in applications where compact size, ease of installation, and reliability are priorities.

Gearbox vs. Geared Motor Difference

The key difference is integration.

- A gearbox is an independent transmission that requires a separate motor.

- A geared motor is a complete drive unit, combining motor and gearbox into one product.

This difference affects everything from system design and installation to maintenance, cost, and performance optimization.

Structural Comparison

| Aspect | Gearbox | Geared Motor |

| Power source | External motor required | Motor included |

| Integration | Mechanical component only | Motor + gearbox combined |

| Installation | Requires alignment with motor | Plug-and-play solution |

| Customization | Highly flexible motor selection | Limited to built-in motor |

| System footprint | Larger overall assembly | Compact and space-saving |

Performance Characteristics

Torque Output

Both gearboxes and geared motors can deliver high torque. However:

- A gearbox allows engineers to pair it with a high-power motor for extremely high torque demands.

- A geared motor offers optimized torque within a predefined power range.

Speed Control

- Gearboxes depend on motor speed and gear ratio selection.

- Geared motors often provide smoother speed control due to optimized matching, especially with servo or BLDC designs.

Efficiency

- Gearbox efficiency varies depending on gear type (planetary and helical are more efficient than worm).

- Geared motors typically achieve higher system efficiency because losses from misalignment and mismatched components are minimized.

Installation and System Integration

Gearbox Installation

Installing a gearbox involves:

- Selecting a compatible motor

- Shaft alignment

- Coupling installation

- Mounting brackets or baseplates

- Vibration and noise considerations

This process offers flexibility but increases installation complexity and potential alignment errors.

Geared Motor Installation

A geared motor:

- Comes pre-assembled and tested

- Minimal alignment required

- Faster installation process

- Reduced misalignment failure risk

For high-volume production lines, this simplicity reduces labor costs and speeds commissioning.

Maintenance and Reliability

Gearbox Maintenance

- Requires periodic lubrication checks

- Seal and bearing inspection

- Coupling wear monitoring

- Motor and gearbox maintained separately

Geared Motor Maintenance

- Fewer mechanical interfaces

- Reduced alignment issues

- Simplified maintenance schedules

- Often lower total maintenance cost

However, if either the motor or gearbox fails, the entire geared motor may need replacement, whereas standalone gearboxes allow individual component replacement.

Cost Considerations

Cost must be evaluated not only in terms of initial purchase price but also total cost of ownership (TCO).

| Cost Factor | Gearbox | Geared Motor |

| Initial purchase | Lower gearbox price, separate motor cost | Higher unit price |

| Installation cost | Higher (alignment, coupling) | Lower |

| Maintenance cost | Moderate to high | Lower |

| Downtime risk | Higher due to complexity | Lower |

| Long-term TCO | Higher in many cases | Often lower |

For small to medium power applications, geared motors usually offer better overall value.

Application Scenarios

When to Choose a Gearbox

A standalone gearbox is preferable when:

- Extremely high torque is required

- Custom motor selection is critical

- Motors need frequent replacement

- Systems require non-standard motors (hydraulic, combustion engine)

- Heavy-duty industrial environments demand robust, oversized components

Typical Applications

- Steel rolling mills

- Mining conveyors

- Cement kilns

- Wind turbine yaw systems

- Heavy lifting equipment

When to Choose a Geared Motor

A geared motor is ideal when:

- Space is limited

- Fast installation is required

- Power range is standardized

- Energy efficiency matters

- Production lines require consistency and scalability

Typical Applications

- Conveyor systems

- Packaging machinery

- Automated assembly lines

- Food processing equipment

- Robotics and AGVs

- Material handling systems

Flexibility vs. Standardization

One of the biggest trade-offs is flexibility.

- Gearboxes offer unmatched flexibility in motor pairing, power scaling, and system customization.

- Geared motors emphasize standardization, repeatability, and ease of deployment.

In modern manufacturing, where downtime and labor costs are critical, standardization often outweighs customization.

Control and Automation Compatibility

Gearbox Systems

- Compatible with VFDs, servo drives, and external encoders

- Requires additional wiring and calibration

Geared Motors

- Often pre-configured for automation

- Servo geared motors integrate seamlessly with motion controllers

- BLDC geared motors enable precise speed and torque control

For Industry 4.0 environments, geared motors simplify integration into smart systems.

Environmental and Safety Considerations

Geared motors typically:

- Reduce noise due to optimized gear meshing

- Minimize oil leakage risks

- Offer sealed designs for washdown or dusty environments

- Improve safety by reducing exposed rotating components

Standalone gearbox systems may require additional guarding and environmental protection.

Scalability in Industrial Design

From an OEM perspective:

- Gearboxes are better for custom machine designs

- Geared motors are better for modular product platforms

Many manufacturers standardize entire product lines around specific geared motor families to simplify inventory and after-sales support.

Future Trends: Integrated Drive Systems

The industry is moving toward higher integration, including:

- Smart geared motors with embedded sensors

- Condition monitoring and predictive maintenance

- Energy-efficient motor-gearbox combinations

- Compact designs supporting decentralized automation

This trend favors geared motors, especially in automated and robotic systems.

Conclusion

While gearboxes and geared motors serve similar mechanical purposes, they address different engineering priorities. A gearbox offers flexibility, scalability, and suitability for extreme conditions, while a geared motor delivers integration, simplicity, and efficiency.

Choosing depends on application suitability, not which option is inherently better. By carefully considering torque requirements, space constraints, installation complexity, maintenance strategy, and long-term operating costs, engineers and buyers can make informed decisions that improve system reliability and overall productivity.