Unlike brushed motors, BLDC motors rely on electronic commutation, meaning that current is switched by an external controller rather than mechanical brushes.

However, despite their advantages, BLDC motors are not immune to operational problems. Engineers and technicians frequently encounter issues such as startup failure, excessive vibration, overheating, or unstable speed control. Understanding these problems — and knowing how to diagnose and correct them — is critical to ensuring reliable and long-term performance.

Understanding BLDC Motor Operation

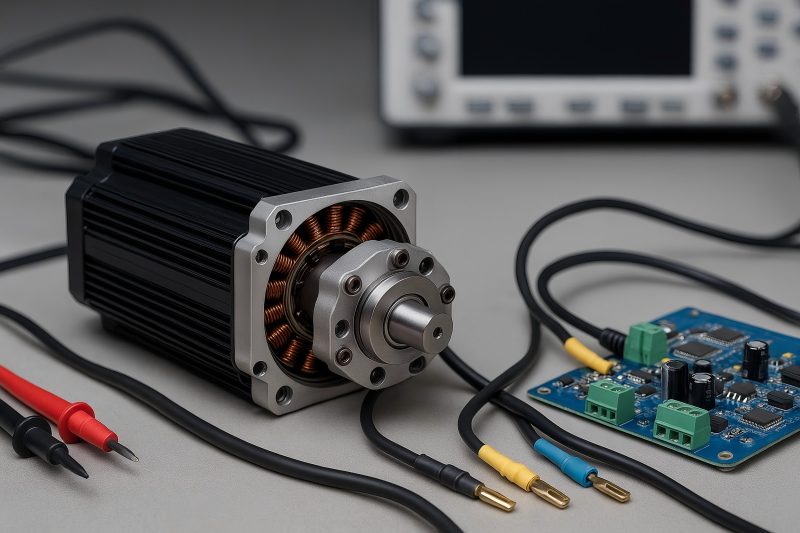

A BLDC motor mainly includes three essential components:

- Stator — with wound copper coils acting as electromagnets.

- Rotor — containing permanent magnets that rotate under electromagnetic force.

- Electronic controller — which controls commutation timing via Hall sensors or back-EMF detection.

Electronic commutation allows BLDC motors to achieve higher efficiency and reduced noise compared with brushed DC motors. However, this reliance on precise timing and feedback also means that any deviation in sensor signals, wiring, or control logic can quickly result in performance degradation or failure.

Motor Fails to Start

Common Causes

- Power supply problems: Insufficient or unstable input voltage is one of the most frequent reasons for startup failure.

- Incorrect controller configuration: If the enable pin, PWM input, or startup sequence parameters are incorrectly set, the motor may not receive a valid command.

- Faulty Hall sensors or signal lines: Damaged sensors or poor wiring connections can prevent the controller from detecting rotor position.

- Open or shorted phase winding: Faults in the stator winding lead to unbalanced current or no electromagnetic torque.

Troubleshooting Steps

- Verify the power source: Measure input voltage under load using a multimeter to ensure it matches rated specifications.

- Check wiring continuity: Inspect phase wires (U, V, W) for damage and confirm correct polarity.

- Examine Hall sensor output: Use an oscilloscope to check square-wave outputs while manually rotating the rotor.

- Inspect controller settings: Confirm that enable pins are active, PWM frequency is compatible, and protection features are not falsely triggered.

- Measure coil resistance: Compare phase-to-phase resistance; significant deviation indicates winding failure.

Motor Runs Roughly or Vibrates

Common Causes

- Phase sequence errors: When the phase order of the motor and controller are mismatched, torque generation becomes unstable.

- Incorrect commutation timing: Improper phase advance or delay leads to torque ripple and vibration.

- Mechanical imbalance: Loose rotor magnets or unbalanced shafts can induce periodic vibration.

- Defective sensors: Misaligned or drifting Hall sensors cause inconsistent feedback.

Troubleshooting Steps

- Check phase wiring: Ensure that the phase order (U-V-W) and Hall sensor sequence correspond to the controller’s expected configuration.

- Inspect rotor and bearings: Remove the rotor and check for mechanical imbalance, cracks, or uneven magnet spacing.

- Test sensor alignment: Re-position Hall sensors so that phase transition occurs at the appropriate electrical angle (typically 60° or 120°).

- Use diagnostic software: Many controllers provide waveform monitoring tools for verifying commutation synchronization.

Overheating During Operation

Common Causes

- Overcurrent or overload: When mechanical load exceeds the rated torque, excessive current flows through windings, generating heat.

- Insufficient cooling: Dust accumulation or inadequate ventilation restricts heat dissipation.

- Controller inefficiency: Poorly tuned PWM switching can cause energy loss in MOSFETs.

- High ambient temperature: Surrounding heat sources can exacerbate internal motor temperature rise.

Troubleshooting Steps

- Measure operating current: Compare actual current draw to the rated value using a clamp meter; overcurrent suggests mechanical overload or control error.

- Improve cooling: Ensure unobstructed airflow, clean vents, or install forced cooling such as a fan or liquid-cooling jacket.

- Verify PWM settings: Check duty-cycle modulation and switching frequency; optimize for minimal switching loss.

- Check bearings: Friction from worn bearings increases heat generation even at normal electrical load.

- Use thermal sensors: Implement temperature monitoring with automatic shutdown thresholds (e.g., 120 °C for stator windings).

Abnormal Noise or Vibration

Common Causes

- Bearing degradation: Over time, bearing lubrication breaks down or contamination enters the raceways.

- Rotor eccentricity: Uneven air gap between rotor and stator causes magnetic imbalance.

- Magnetic noise: Resulting from asymmetric magnetization or partial demagnetization.

- Resonance with mounting structure: Vibrations can amplify at specific frequencies.

Troubleshooting Steps

- Inspect bearings: Spin the shaft by hand; any roughness or grinding indicates bearing wear. Replace if necessary.

- Check mechanical alignment: Measure the air-gap uniformity using a feeler gauge.

- Analyze vibration spectra: Use a vibration analyzer to identify the dominant frequency and trace it to mechanical or electrical sources.

- Add damping materials: Rubber mounts or isolation pads help absorb structural resonance.

- Ensure precise assembly: Misalignment between motor housing and load shaft often amplifies noise.

Loss of Torque or Speed Fluctuation

Common Causes

- Demagnetization of rotor magnets: High temperature or overcurrent may reduce magnet strength.

- Phase imbalance: One phase not conducting properly lowers torque output.

- Voltage drop: Long cable runs or weak power supplies lead to unstable speed.

- Temperature drift: Increased resistance in copper windings reduces effective torque at higher temperatures.

Troubleshooting Steps

- Measure back-EMF waveform: Deviation in amplitude between phases indicates magnet degradation.

- Check supply voltage stability: Use an oscilloscope to monitor voltage ripple during load changes.

- Inspect connectors: Loose terminals create intermittent voltage drops.

- Test phase currents: Compare using a current probe to confirm equal current in all three phases.

- Evaluate thermal design: Add heat sinks or active cooling if torque loss is temperature-related.

Erratic or Unstable Operation (Jittering, Reversing, or Stalling)

Common Causes

- Signal noise or interference: Electromagnetic interference (EMI) corrupts Hall sensor or encoder signals.

- Firmware bugs or improper PID tuning: Incorrect control parameters cause oscillation or overshoot.

- Grounding and shielding issues: Improper cable layout causes interference between power and signal.

- Loose connectors: Intermittent connections lead to false position feedback.

Troubleshooting Steps

- Improve signal integrity: Use twisted-pair cables for Hall lines and ground the shield at one end only.

- Add EMI suppression: Install ferrite beads and capacitors on power lines to minimize conducted noise.

- Update firmware: Many modern drives fix stability problems via firmware revisions.

- Adjust control loop parameters: Properly tune proportional, integral, and derivative (PID) gains to balance responsiveness and stability.

- Isolate motor power from logic power: Use separate grounding paths to prevent feedback interference.

Preventive Maintenance for BLDC Motors

While troubleshooting resolves existing problems, preventive maintenance minimizes the chance of recurrence and extends motor life.

Key Practices:

- Routine inspection: Periodically check connectors, insulation, and fasteners.

- Bearing maintenance: Re-lubricate or replace bearings after recommended service intervals.

- Controller updates: Keep firmware current to benefit from improved algorithms and protection features.

- Environmental control: Maintain clean, dry surroundings; prevent dust and moisture ingress (use IP-rated housings if necessary).

- Thermal monitoring: Implement NTC sensors or thermistors within windings to detect over-temperature conditions early.

- Electrical testing: Perform insulation resistance tests (Megger) and surge tests to detect degradation before failure.

These measures help maintain consistent torque output, efficiency, and reliability across the motor’s operational life.

Summary Table: Problems, Causes, and Solutions

| Problem | Possible Causes | Troubleshooting Actions |

| Motor fails to start | Power issue, faulty sensor, open winding | Verify power, test Hall sensors, check continuity |

| Rough running or vibration | Phase mismatch, timing error, imbalance | Re-align phase order, adjust timing, inspect rotor |

| Overheating | Overload, poor cooling, friction | Reduce load, clean vents, replace bearings |

| Noise or vibration | Bearing wear, eccentricity | Replace bearings, check air gap |

| Torque loss or speed fluctuation | Demagnetization, voltage drop | Test back-EMF, stabilize supply |

| Erratic motion | EMI, firmware, loose connections | Add shielding, update firmware, secure connectors |

Best Practices for Reliable BLDC Motor Operation

To ensure long-term operational stability, consider these professional guidelines:

Proper Motor-Controller Matching:

Always select a controller that supports the motor’s electrical parameters — voltage, current, and number of pole pairs. Mismatched configurations are among the most frequent root causes of operational issues.

Accurate Sensor Alignment:

During assembly or maintenance, verify that Hall sensors are positioned precisely relative to the stator slots. Even slight misalignment can greatly reduce torque smoothness.

Balanced Load Coupling:

Avoid direct coupling of unbalanced mechanical loads. Use flexible couplings to reduce stress on the shaft and bearings.

Cable Management:

Keep power cables separate from signal lines to minimize EMI. Proper grounding and ferrite rings improve system robustness.

Thermal Design Considerations:

For continuous high-torque applications, integrate heat sinks, forced-air cooling, or even liquid cooling into the design to maintain winding temperature below insulation limits.

Continuous Monitoring Systems:

Incorporate real-time monitoring of temperature, vibration, and current draw via IoT sensors. Predictive maintenance based on trend analysis can prevent costly downtime.

Brushless DC motors deliver outstanding performance and longevity when operated under controlled conditions. Most operational issues — from startup failure to overheating or instability — arise from electrical misconfiguration, mechanical misalignment, or inadequate thermal management.

By systematically analyzing the symptoms, identifying root causes, and applying structured troubleshooting steps, engineers can restore normal performance quickly and reliably. Preventive maintenance, proper system design, and continuous monitoring further ensure that BLDC motors operate efficiently and safely throughout their service life.

Ultimately, proactive troubleshooting isn’t just about fixing problems — it’s about preserving performance, optimizing productivity, and extending the lifespan of your motion systems.