E-bikes and scooters revolutionize cities with efficient, eco-friendly, and affordable alternatives to traditional vehicles. At the heart of these vehicles lies a motor—often a Brushless DC (BLDC) motor—that determines acceleration, efficiency, weight distribution, and even maintenance requirements.

Two popular BLDC motor architectures dominate the market: inrunner and outrunner designs. While outrunners are well-known for their torque-rich, lower-speed operation, inrunners excel in high-RPM performance and compact form factors.

In the context of e-bikes and scooters, the choice between inrunner and outrunner is not always obvious. This article examines when to prefer inrunner BLDC motors over outrunner designs, supported by technical data, application insights, and real-world considerations for manufacturers, fleet operators, and riders.

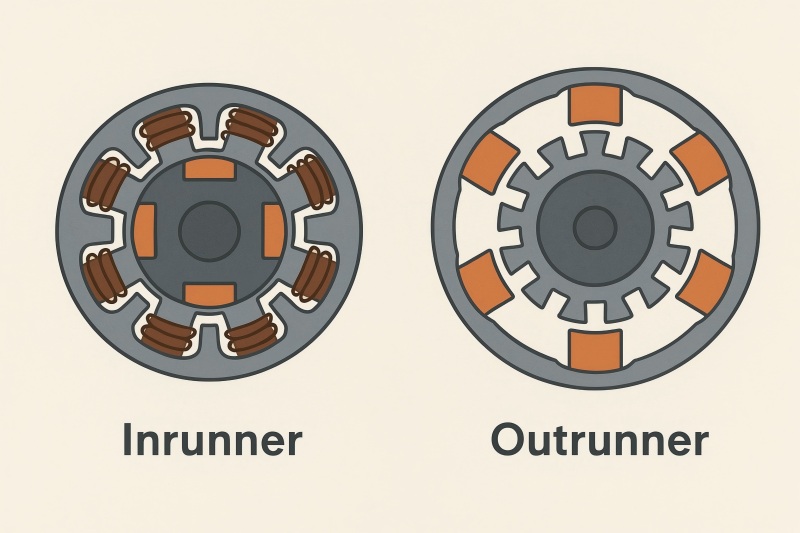

Basics of Inrunner and Outrunner BLDC Motors

Before comparing their roles in e-bikes and scooters, it’s worth understanding the key mechanical differences.

Inrunner BLDC Motor

- Rotor with magnets spins inside stator windings.

- Rotor spins within a fixed outer casing.

- Typically optimized for high-speed, low-torque output.

- Often requires gear reduction to match wheel torque demands.

Outrunner BLDC Motor

- The rotor sits outside the stator windings.

- Outer shell spins around a fixed inner core.

- Naturally produces high torque at lower RPMs.

- Often used in direct-drive applications without gears.

Why Motor Choice Matters for E-Bikes and Scooters

Motor selection affects:

- Acceleration and Climbing Performance – Torque output impacts hill climbing and load carrying.

- Top Speed – Depends on RPM and gearing.

- Energy Efficiency – Influences battery range.

- Motor Size and Weight – Affects handling and portability.

- Durability and Maintenance – Important for fleet use.

Technical Advantages of Inrunner BLDC in E-Bikes and Scooters

While outrunner motors dominate in some budget-friendly and mid-range scooter/e-bike models, inrunner BLDC motors are often the better choice in the following situations:

High-Speed Commuting and Sport Models

Inrunner motors are designed to spin faster—often up to 50,000 RPM in high-end variants. With proper gearing, they can sustain higher top speeds without overheating.

Example: Performance e-bikes targeting speeds above 40 km/h often choose inrunner motors with internal gear reduction.

Space-Constrained or Aerodynamic Designs

Inrunner BLDC motors are generally smaller in diameter but longer in length compared to outrunners. This shape fits better in:

- Compact scooter decks

- Integrated mid-drive units

- Streamlined e-bike frames

Better Thermal Management

Because the stator (heat-generating part) is on the outside in an inrunner, heat dissipation is more efficient. This is critical for:

- High-power hill climbing

- Heavy rider loads

- Continuous long-distance commuting

Precision Control and Smoothness

Inrunners tend to have lower torque ripple and better Field-Oriented Control (FOC) compatibility, making them ideal for:

- Adaptive cruise control in premium e-bikes

- Smooth acceleration profiles for shared scooters

Performance Data: Inrunner vs Outrunner in E-Bike and Scooter Use

| Parameter | Inrunner BLDC Motor (Mid-Drive) | Outrunner BLDC Motor (Hub Drive) |

| Typical RPM Range | 5,000 – 50,000 RPM | 200 – 2,000 RPM |

| Torque at Motor Shaft | Lower (requires gearing) | High (direct-drive capable) |

| Efficiency at High Speed | 90–94% | 80–88% |

| Weight-to-Power Ratio | 0.5–1.0 kg/kW | 0.8–1.5 kg/kW |

| Motor Diameter | Small (40–80 mm typical) | Large (80–200 mm typical) |

| Heat Dissipation | Better (stator outside) | Limited (stator inside) |

| Maintenance Needs | Low (sealed gear systems) | Low (direct drive) |

| Ideal Use Case | High-speed, compact, premium models | Budget, torque-rich commuter models |

When Inrunner BLDC Motors Outperform in Real E-Bike/Scooter Scenarios

High-Performance Commuter E-Bikes

If the target is speed + efficiency, an inrunner with gearing can outperform an outrunner in acceleration and sustained high-speed riding.

Case Example:

- Motor: 1.5 kW inrunner, geared mid-drive

- Top Speed: 48 km/h

- Efficiency: 92% average at 35 km/h cruising

- Use Case: Long-distance commuters on flat-to-moderate terrain

Shared E-Scooters in Hot Climates

Inrunner BLDCs handle thermal stress better, reducing shutdown incidents in summer urban use. Fleet operators benefit from reduced downtime.

Case Example:

- Motor: 500 W inrunner hub (sealed cooling channels)

- Ambient Temp: 35°C+

- Heat Soak Test: Maintained under 75°C core temp after 1 hour continuous use

Hill-Climbing Delivery E-Bikes

With proper gearing, inrunners can deliver sustained torque without overheating, crucial for cargo e-bikes and delivery fleets.

Case Example:

- Motor: 2.0 kW inrunner mid-drive with planetary gear

- Load: 120 kg cargo + rider

- Climb Test: 10% grade for 3 km without thermal rollback

Cost Considerations

While inrunner BLDC motors tend to be more expensive than outrunners (due to higher precision machining and often integrated gearing), the total lifecycle cost can be lower:

- Longer lifespan due to better cooling

- Lower battery consumption at high speeds

- Reduced fleet maintenance downtime

Drawbacks of Inrunner BLDC in E-Bikes/Scooters

Lower Native Torque – Requires gears or belt reduction.

Higher Initial Cost – More expensive manufacturing and control electronics.

More Complex Installation – Especially for mid-drive designs with integrated gearing.

Selection Guidelines for Manufacturers and Riders

| Requirement | Prefer Inrunner BLDC If… |

| Top Speed > 40 km/h | Yes |

| Long Continuous Rides | Yes – Better heat handling |

| Compact Frame Design | Yes – Small diameter advantageous |

| High Torque at Low Speed | No – Outrunner or geared inrunner preferred |

| Budget Constraints | No – Outrunner is more cost-effective |

| Premium Riding Experience | Yes – Smoothness and control advantages |

Market Trends for Inrunner BLDC in Light EVs

According to industry data (2024), inrunner BLDC adoption in premium e-bikes and scooters is increasing:

- Global Light EV BLDC Motor Market: $9.5B in 2024, projected to reach $13.2B by 2028.

- Inrunner Share in Premium Segment: 38% in 2024, projected to exceed 50% by 2028.

- Key Growth Drivers: Thermal performance, compact design, efficiency in high-speed models.

While outrunner BLDC motors still dominate the affordable commuter e-bike and scooter market thanks to their simplicity and torque-heavy characteristics, inrunner BLDC motors excel in scenarios demanding:

- Higher sustained speeds

- Better cooling in hot climates

- Compact or aerodynamic frame integration

- Premium ride smoothness and control

For manufacturers aiming to build high-performance, reliable, and efficient light EVs—especially in urban and fleet applications—the inrunner BLDC is often the smarter choice.