Outrunner BLDC (Brushless DC) motors are widely used in drones, RC aircraft, hobby robotics, and e-bike applications due to their high torque-to-weight ratio and efficiency. A critical component of any system using BLDC motors is the Electronic Speed Controller (ESC)—the interface between your control signals (like PWM or other protocols) and the power delivered to the motor.

Choosing the right ESC involves understanding how ESCs operate, the types of control methods they support (PWM vs FOC), voltage and current ratings, and other features such as telemetry, cooling, and firmware. In this guide, you’ll learn about:

- ESC operation principles

- Control methods: PWM vs FOC

- Voltage considerations

- Current ratings and continuous vs peak current

- Efficiency and thermal management

- Additional features

- Selection checklist and comparison tables

- Example ESC and motor pairings

- Summary and recommendations

ESC Operation: Basics

An ESC takes a low-voltage control input (such as PWM from a flight controller) and switches higher-voltage DC to the three-phase windings of a BLDC motor in a specific sequence to rotate it. This involves:

- High-speed MOSFET switching to drive phases

- Commutation logic to decide which phases to power

- Sensing (back-EMF or sensors) for position feedback

- Protection circuits for over-voltage, over-current, low-voltage cutoff (LVC)

Key metrics:

- Voltage rating (V): max battery voltage ESC can handle

- Continuous current (A): current ESC can sustain indefinitely, limited by cooling

- Burst current (A): short-time high current capability (e.g., 10 seconds)

- Control method: PWM (six-step) or FOC (field-oriented control)

- Firmware: e.g., BLHeli, KISS, VESC, specialized FOC firmware

Control Methods: PWM vs FOC

PWM / “Six-Step” Control

Traditional method—ESC drives motor with six-step commutation.

Simpler, less computational overhead, but:

- Produces stepped waveform—more ripple and torque ripple.

- No optimal current vector control → slightly less efficient, noisier.

FOC (Field-Oriented Control)

Implements vector control to drive motor based on real-time rotor/stator field orientation.

Delivers:

- Extremely smooth torque and rotation.

- Lower electrical noise, less motor heating.

- Higher efficiency, especially at low RPM and partial loads.

Requires more processing power and sometimes current and voltage sensing (like VESC-based ESCs).

Comparison Table

| Feature | PWM (Six-Step) | FOC (Field-Oriented Control) |

| Commutation | Six-step | Vector (sinusoidal) |

| Smoothness | Moderate; torque ripple | Very smooth, minimal torque ripple |

| Efficiency | Good, less at low RPM | Excellent across wide RPM range |

| Noise (audible) | Higher (buzzing) | Quieter |

| Complexity / Cost | Lower | Higher (needs advanced microcontroller, sensors) |

| Firmware Examples | BLHeli, KISS (non‐FOC) | VESC, BLHeli_S (FOC), custom FOC |

Voltage Considerations

ESC voltage rating must match the battery and motor voltage requirements:

- Common ESC ratings: 2S to 6S LiPo (7.4 V to 22.2 V), or in e-bike/hobby-grade: 24 V, 36 V, 48 V, etc.

- Margin is essential—choose ESC rated slightly higher than nominal battery voltage to accommodate voltage spikes and overshoot.

Voltage–Battery Examples

| Application | Battery Type | Nominal Voltage | ESC Voltage Rating |

| Mini drone | 3 S LiPo | ≈11.1 V | 3 S–4 S (12 V–16.8 V) |

| FPV racing drone | 4 S LiPo | ≈14.8 V | 4 S–5 S (16.8 V–21 V) |

| E-bike / Scooter | Li-ion pack | ≈36 V | 36 V–48 V |

| larger e-Rover | Li-ion pack | ≈48 V | 48 V–60 V |

Always ensure ESC’s max voltage rating exceeds peak voltage under load (fully charged LiPo ~4.2 V per cell).

Current Ratings: Continuous vs Burst Current

Selecting current rating is perhaps the most critical part.

- Continuous current: max current ESC can handle indefinitely (typically with proper cooling).

- Burst current: short-term rating, e.g., 5–10 seconds.

Always compare the ESC rating to the expected current draw of your motor at your operating conditions.

Example Motor Current Data

Let’s suppose an outrunner BLDC motor has these measured current draws:

| Load Condition | Voltage | Current Draw |

| Idle (no load) | 12 V | 0.5 A |

| Hover / light load | 12 V | 10 A |

| Max throttle / heavy | 12 V | 20 A |

| Stall | 12 V | 25 A |

In this case, the ESC should:

- Sustain at least 20 A continuous

- Handle 25 A burst for safety and startup

ESC Current Ratings Table (Example Models)

| ESC Model | Voltage (S LiPo) | Continuous Current | Burst Current | Control Type |

| ESC-A (budget) | 2–4 S | 20 A | 25 A (5 s) | PWM |

| ESC-B (mid-range) | 3–6 S | 30 A | 40 A (10 s) | PWM / FOC |

| ESC-C (hi-end) | 4–6 S | 40 A | 60 A (10 s) | FOC only |

| ESC-D (e-bike style) | 10S (~36 V) | 100 A | 150 A (10 s) | FOC |

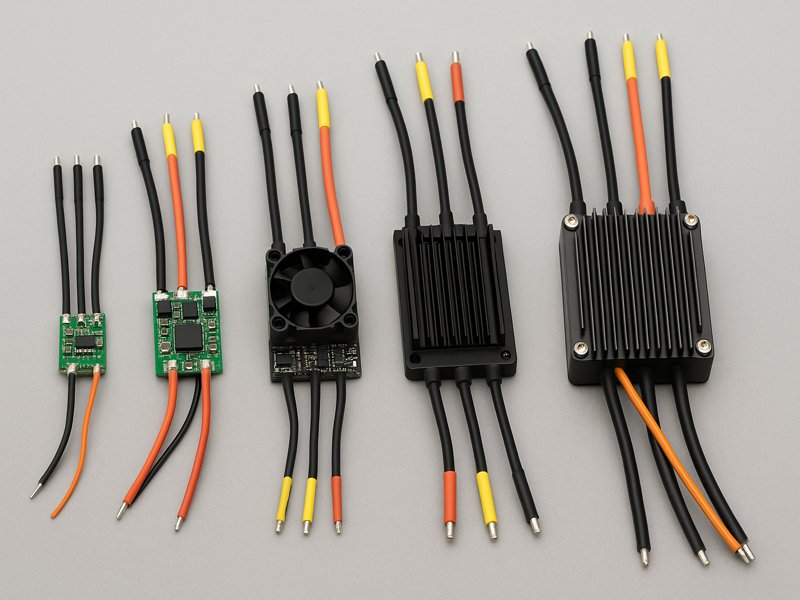

Efficiency & Thermal Management

Heat is your ESC’s worst enemy. Efficiency and cooling strategies dramatically affect performance and longevity.

Efficiency differences: FOC ESCs often run ~2–5% more efficient under partial load. In a 12 V system pulling 20 A (240 W), 5% saving is a meaningful 12 W reduction in heat.

Cooling methods:

- Passive: aluminum heat sinks, airflow

- Active: integrated or add-on fans

- Liquid cooling: for high-power installations

| ESC Type | Cooling Method | Typical Temp Rise | Comment |

| Budget PWM ESC | Passive fins + airflow | +30 °C | May require external airflow |

| Mid-range FOC ESC | Fins + small fan | +20 °C | Better high-load performance |

| High-end FOC ESC | Large fins + fan | +10 °C | Seldom thermal throttling |

Additional Features to Consider

Telemetry support – ability to report RPM, current, voltage, temperature to your flight controller.

BEC (Battery Eliminator Circuit) – integrated 5 V/6 V regulator for powering radio/receiver:

Rated in amps: e.g., 2 A, 3 A.

Programmability – via USB link, Bluetooth, or dedicated curser-pot interface.

Brake support – useful in e-bikes and robotics.

Startup modes – soft start, active braking, brake-to-zero, motor timing adjustment.

Firmware support:

- BLHeli: common for multirotor drones, usually supports both PWM and FOC variants

- VESC firmware: widely used in e-skates, robotics, advanced FOC tuning

ESC Selection Checklist & Comparison

ESC Selection Checklist

- Voltage compatibility: ESC max voltage > battery peak voltage

- Current capacity: Continuous ≥ steady-state draw; Burst ≥ startup/stall and peak spikes

- Control method: PWM if cost-sensitive; FOC for efficiency, noise, smoothness

- Cooling solution: fuse heat path with motor load profile

- Desired features: telemetry, BEC, programming, braking, startup handling

- Form factor & weight: important for drones and mobile platforms

- Firmware & community support: availability of tuning, updates, docs

Sample Comparison Table

| ESC Model | Voltage | Cont. Current | Burst Current | Control Type | Cooling | Telemetry | BEC | Notes |

| ESC-A | 2–4 S | 20 A | 25 A | PWM | Passive fins | No | 5 V/2 A | Budget drone ESC |

| ESC-B | 3–6 S | 30 A | 40 A | PWM/FOC | Small fan | Yes | 5 V/3 A | Mid-range, multicopter ready |

| ESC-C | 4–6 S | 40 A | 60 A | FOC | Fan + fins | Yes | 6 V/3 A | Racing-grade, smooth FOC |

| ESC-D (e-bike) | 10 S | 100 A | 150 A | FOC | Large fins + fan | Yes | No | High-torque e-bike systems |

Example Pairings: Motor & ESC

Example 1: Mini Racing Drone

- Motor: 2205 size, KV 2300, draws ~15 A at full throttle on 4 S battery

- Battery: 4 S LiPo (nom. 14.8 V, peak ~16.8 V)

- ESC: Needs ≥ 20 A continuous, ~25 A burst, rated 5 S for overhead; smooth control → ESC-B (3–6 S, 30 A cont., 40 A burst, PWM/FOC, small fan)

Example 2: E-bike Drive Motor

- Motor: Outrunner geared hub, draws 60 A at peak, 30 A cruising on 36 V battery (10 S)

- Battery: Nominal 36 V (~42 V peak)

- ESC: Needs ≥ 30 A cont., ≥ 60 A burst; FOC preferred for smoothness and regen. ESC-D (10 S, 100 A cont.) fits.

Example 3: RC Boat with Heavy Load

- Motor: Large outrunner, draws 25 A cont., 50 A peak on 6 S

- Battery: 6 S LiPo (22.2 V nom, 25.2 V peak)

- ESC: Needs ≥ 30 A cont., ≥ 60 A burst; FOC gives quieter operation in watercraft. Choose ESC-C (4–6 S, 40 A cont., 60 A burst, FOC)

Notes on Matching ESC and Motor Spec Data

Calculate approximate motor current via motor datasheet or measurement with tachometer and wattmeter.

Motor heat and ESC heat must be within safe limits—monitor component temps during initial trials.

Consider voltage sag under load—cells may droop from 4.2 V to 3.7 V or lower; choose ESC margin accordingly.

Upgrading your ESC (and taking advantage of FOC) can improve battery life, reduce heat, and make throttle feel more responsive.

Wrap-Up & Recommendations

PWM ESCs are cost-effective and perfectly fine for many applications—choose a model with sufficient voltage and current rating.

FOC ESCs are worth the additional cost for smoother, more efficient operation—especially for robotics, e-bikes, boats, and noisy or precision applications.

Always overspec on voltage and current to ensure reliability and thermal margin.

Required features (telemetry, BEC, braking) should reflect your control system and convenience needs.

Use example pairing tables above as templates for selecting ESCs for your outrunner BLDC projects.